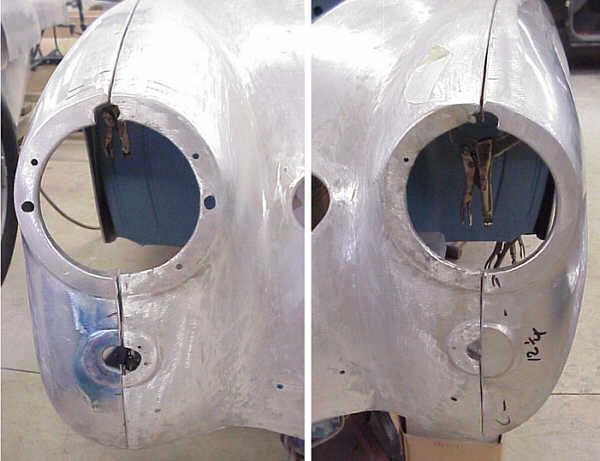

The image above shows work progressing on the alloy front

wings. Note on the left image (right wing) that the profile of the wing

toward the bottom has been modified to match that of the original wing

shown on page two. While the right image shows the left wing before the

profile has been modified. Also note in both images, the misalignment of

the raised area for the side lights with the corresponding area on the

shroud.

Note that the door frames are steel like later cars,

unlike 100S alloy doors with alloy frames

The alloy skin reinstalled on the door frame, the process of aligning the door gaps being carried out to an exacting standard. The original door skins were removed, repaired in their lower sections and refitted

Work in progress on the rear end of the car, note that the rear right wing has now been reworked to match the rear shroud, for those familiar with Healey wings, also note the wider contour.

The backing on the new armacord is shown above being carefully trimmed back to the same thickness as the original. A long and tedious task!

Note the misalignment between the windscreen post and wing, another area requiring rework to make later parts fit this early car.

One of the many interesting differences on this car is that the swage line is a convex radius rather than the usual concave.

After completion of the wing modifications, the gravel tray fitted, and trial installation of headlamps and parking lamps. To correctly align the latter, a new raised base had to be fabricated on the wings.

The panel work completed by Mike Lewis, On Sept 20th 2001, the car was trailered to Quality Restoration Services, to continue the body and frame restoration.

Page 4