The Restoration of the First Production Austin Healey

100

Page 5

Updated February 2002

"There is a point that you reach with every restoration

at which you have taken things so far apart that any further work can only

be considered assembly. We are there."

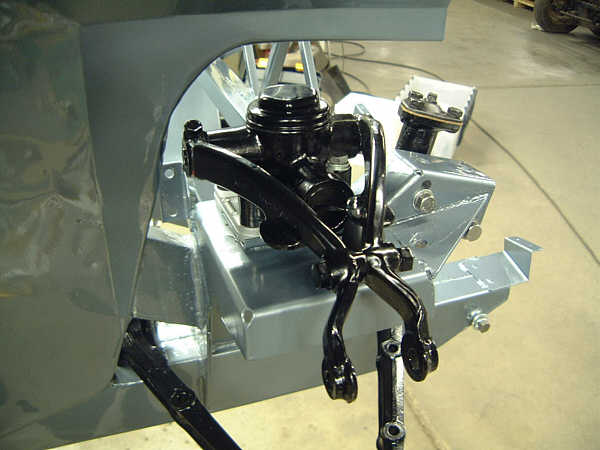

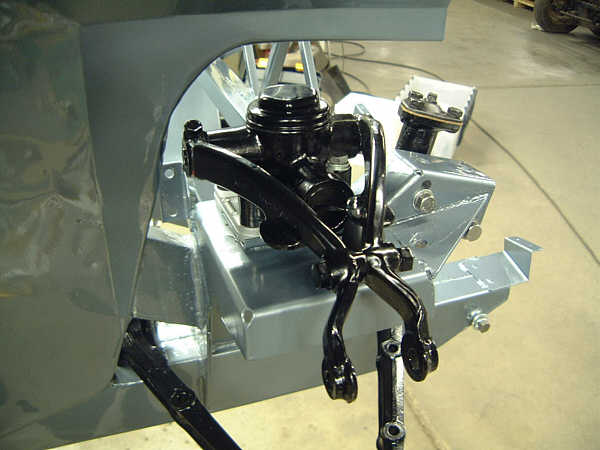

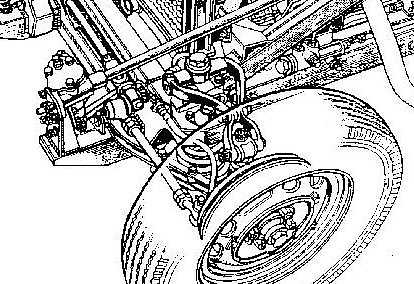

Richard Chrysler has the honour taking this first step

in our new direction. He starts with the front suspension. Note that

this car is fitted with Girling shock absorbers (shown below)

The very early cars had a cast aluminium shock mount

rather than a steel weldment for a perch. The shock travel bumper

is also mounted on a solid aluminium base which puts it at the same level

as the base of the shock absorber.

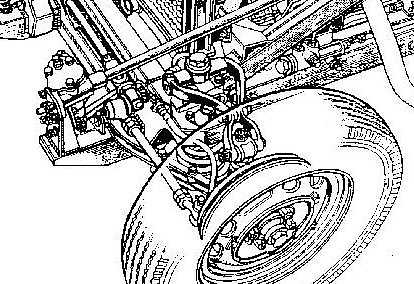

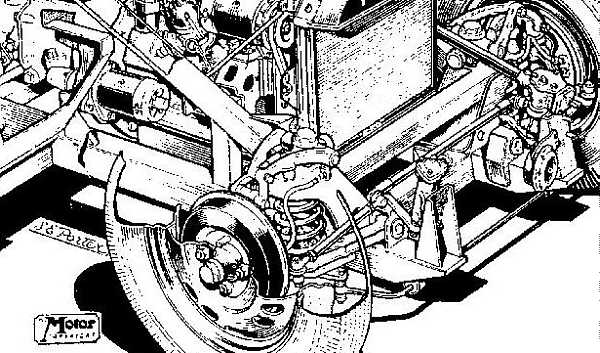

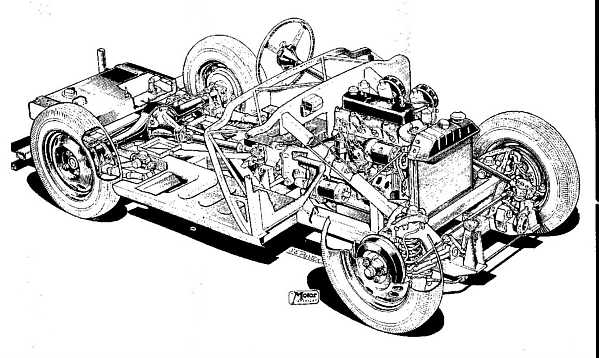

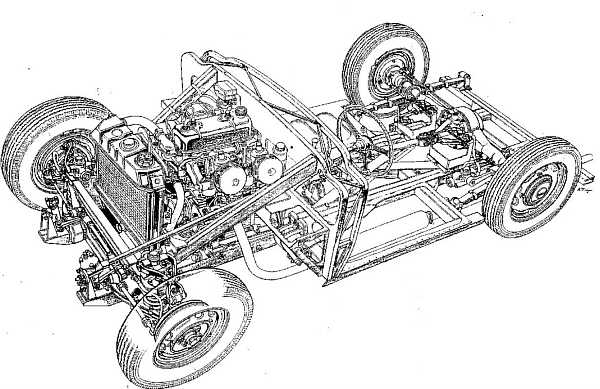

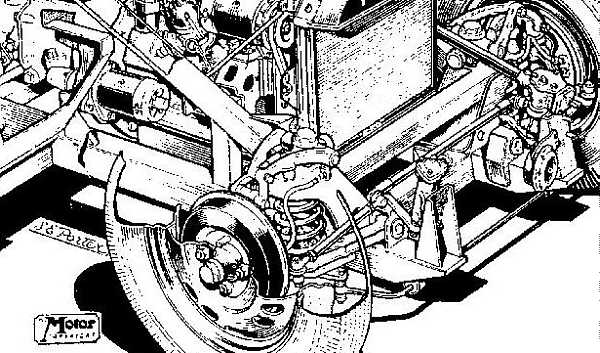

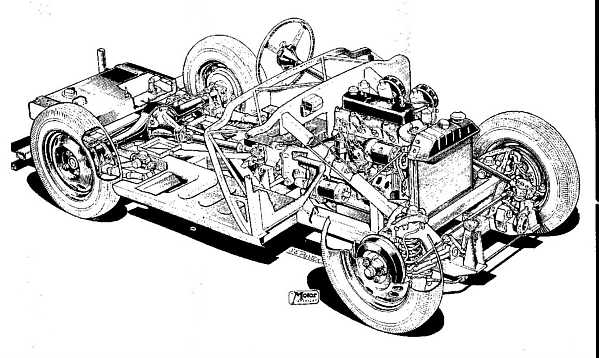

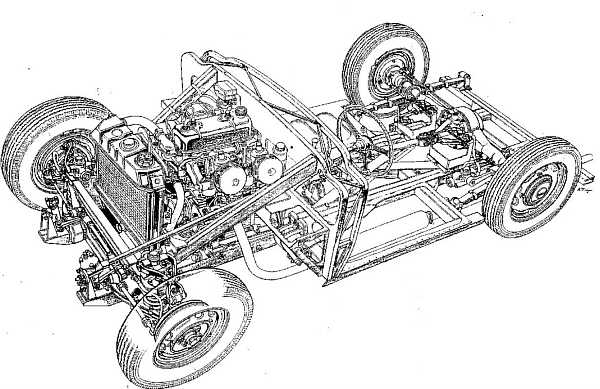

As a matter of interest, above and below are cutaway

drawings from the Autocar and Motor publications that amongst other interesting

differences show the same shock absorbers on the prototype Austin Healey

100

This picture shows the current progress at the front

end of the chassis. Brakes and steering are to follow.

The seat bases for these early cars were very much a hand

made weldment. There are no stampings and are fabricated in pieces

and welded together. The seat backs are aluminium with two

stiffening ribs indented horizontally. They are a different shape

from those of later production cars. The bases were located in the car

with measurements taken from the original floor panels of both this car

and AHX14.

The seat bases for these early cars were very much a hand

made weldment. There are no stampings and are fabricated in pieces

and welded together. The seat backs are aluminium with two

stiffening ribs indented horizontally. They are a different shape

from those of later production cars. The bases were located in the car

with measurements taken from the original floor panels of both this car

and AHX14.

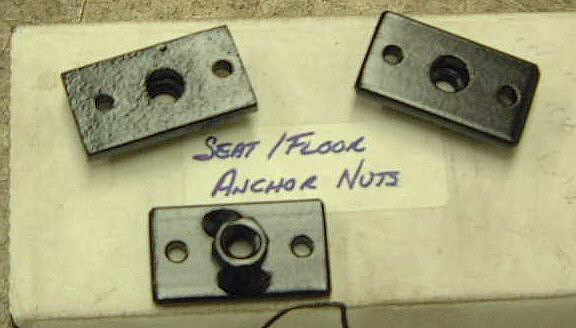

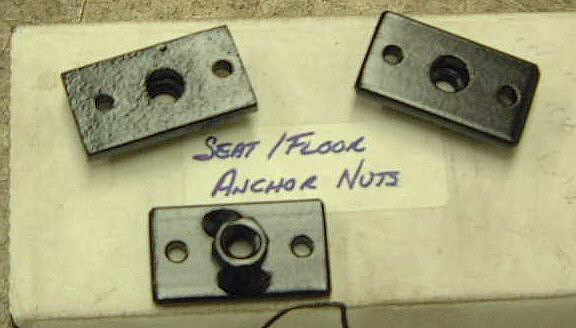

The seats are held in position by bolts that anchor into

weld nuts located beneath the floor. This picture shows one of the

original anchor nuts shown in the top left, and the top and underside of

two which Blair made up.

The door sills on these cars are made in the fashion that

DMH complained about to Jensen Motors. Note in the image above that

the top surface is flat, missing the step toward the outer edge. The step

in the sill is built up by the addition of a piece of wood located underneath

the embossed aluminium trim plate as shown below.

The taper shaped wood is about 5/16” thick and is screwed

in place to make a step onto the flat steel sill.

The aluminium trim is then screwed along the top edge

of the upper sill, and the outer edge of the wood.

The image above shows the original Aluminium trims that

were used as patterns for the replacements

The door strikers are similar to those used on MG TC’s

and are located in a depression formed in the trim panel. All of the original

aluminium trim panels are with the car and were excellent patterns for

the fabrication of new ones. The embossed material was supplied in

the flat by Kilmartin Automotive Sheet metal.

Above and below, more section views of the original prototype

100

The backing plate for the door striker and the gussets

with lightening holes.

The armacord material was painted with Mar-Hyde dye to

get the correct colour for the interior. It is a very dark and navy

blue. The everflex material was also done, but with a flattener

added since it is to be dull in comparison to the armacord.

Yards of ICI vinyl were purchased from Heritage Upholstery

and Trim of Vancouver B.C. and the convertible top is also on order with

them as well. Their material looks excellent and we will be able

to attain nice tight edging for the interior trim because it is nice and

thin in comparison to the everflex. All of the materials have been

take to John Smyth of Heritage Coach Trimming in Brampton, Ontario who

did the interior for AHX14. All of his patterns will be re-fitted

and used for this car. Before the car is delivered, he is going to

start on the seats and arm rest since they represent a large amount of

work. He is shown here with one of the seats from the AHX14 restoration.

Yards of ICI vinyl were purchased from Heritage Upholstery

and Trim of Vancouver B.C. and the convertible top is also on order with

them as well. Their material looks excellent and we will be able

to attain nice tight edging for the interior trim because it is nice and

thin in comparison to the everflex. All of the materials have been

take to John Smyth of Heritage Coach Trimming in Brampton, Ontario who

did the interior for AHX14. All of his patterns will be re-fitted

and used for this car. Before the car is delivered, he is going to

start on the seats and arm rest since they represent a large amount of

work. He is shown here with one of the seats from the AHX14 restoration.

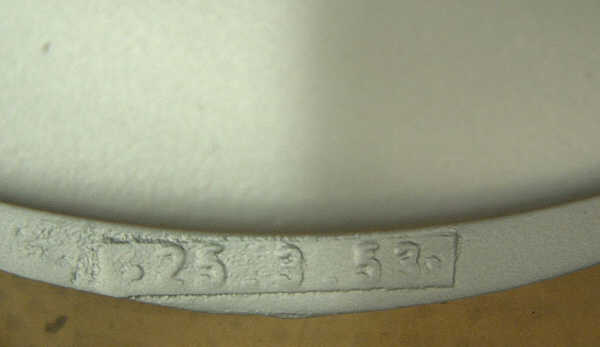

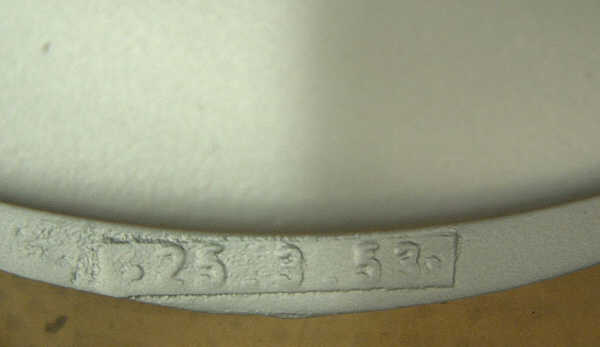

Included out of interest in these early cars, this is one

of the rear brake drums that are originally from AHX14. They were

originally chrome plated. Richard Chrysler mentioned that this would

indicate that it would have been fitted with chrome wheels originally.

It would most likely have been part of shows or demonstrations with the

introduction of the Austin Healey 100.

Included out of interest in these early cars, this is one

of the rear brake drums that are originally from AHX14. They were

originally chrome plated. Richard Chrysler mentioned that this would

indicate that it would have been fitted with chrome wheels originally.

It would most likely have been part of shows or demonstrations with the

introduction of the Austin Healey 100.

The casting date on this brake drum is March 25th, 1953.

The door hinges on both of the pre-production cars and

the first production car all have straight slotted screws on the door hinges.

These are all BSF.

This is the clutch and brake pedal cover plate. It

seems they had trouble enough aligning the holes with the pedals, and went

to a separate plate that allowed for wider spacing of the pedal holes.

The original holes on the RHD side would also be to close to each other

to accommodate the pedals as well.

This is the clutch and brake pedal cover plate. It

seems they had trouble enough aligning the holes with the pedals, and went

to a separate plate that allowed for wider spacing of the pedal holes.

The original holes on the RHD side would also be to close to each other

to accommodate the pedals as well.

The first production car is in good company. This picture

shows body #174 in the foreground, AHX-12 in red paint with racing stripes,

and AHX-14 in the background. The first production car is being assembled

on the hoist to the right. It has been invaluable to be able to refer

to these other cars for this restoration.

The first production car is in good company. This picture

shows body #174 in the foreground, AHX-12 in red paint with racing stripes,

and AHX-14 in the background. The first production car is being assembled

on the hoist to the right. It has been invaluable to be able to refer

to these other cars for this restoration.

#174 is a great example of authenticity. This picture

shows some of the heat shield shape and mounting hardware etc. The

hole locations align with those on chassis #138031 and are great for reference.

This car has all of its original wiring system, components, and hardware

in tact. At the same time, several changes were made with the frame

construction and body parts for this car when compared to the first production

car.