Healeys are well known for their scuttle

shake, the modification shown above will ( I hope ) reduce this. I have

used a piece of 20x6 flat steel and welded it to the inside of the chassis

rail and to the bottom face of the cold air box. It is also plug welded

to the sheet metal footwell flange. Rather than using self tapping screws

to told the gearbox aperture panel, I have drilled and tapped the flat

steel so that the whole assembly can be screwed up tight.

Healeys are well known for their scuttle

shake, the modification shown above will ( I hope ) reduce this. I have

used a piece of 20x6 flat steel and welded it to the inside of the chassis

rail and to the bottom face of the cold air box. It is also plug welded

to the sheet metal footwell flange. Rather than using self tapping screws

to told the gearbox aperture panel, I have drilled and tapped the flat

steel so that the whole assembly can be screwed up tight.

The camber adjustment kit shown tacked into

position above was manufactured by Theo Van Heel in Melbourne. It consists

of a new ( Raked ) top cap, A high tensile tapped block, and high tensile

mounting and adjusting set screws. After looking at the options available

I preferred this method of adjusting the suspension camber to suit modern

tyres.

The camber adjustment kit shown tacked into

position above was manufactured by Theo Van Heel in Melbourne. It consists

of a new ( Raked ) top cap, A high tensile tapped block, and high tensile

mounting and adjusting set screws. After looking at the options available

I preferred this method of adjusting the suspension camber to suit modern

tyres.

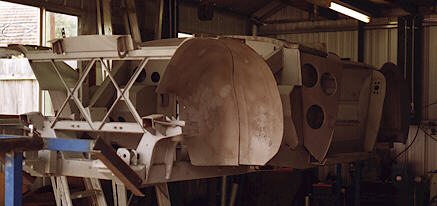

The chassis assembly is now sandblasted and

fitted into it's roll over frame ready for painting. The sandblasting blew

holes through the rear inner guards in a couple of places that I thought

were solid enough. Now I know why many restorers pre blast before starting

chassis work! After repairing the inner guard front dog leg and now the

rear it would probably have been easier to replace the whole inner guard.

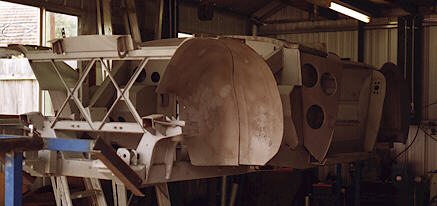

The chassis assembly is now sandblasted and

fitted into it's roll over frame ready for painting. The sandblasting blew

holes through the rear inner guards in a couple of places that I thought

were solid enough. Now I know why many restorers pre blast before starting

chassis work! After repairing the inner guard front dog leg and now the

rear it would probably have been easier to replace the whole inner guard.

Page

9

Home