Rear left pillar with the lead stripped and a couple of cracks re welded

Rear left quarter with the lower section of wheel arch replaced.

The rear left quarter repaired, light spots indicate shrinks to removed stretched metal.

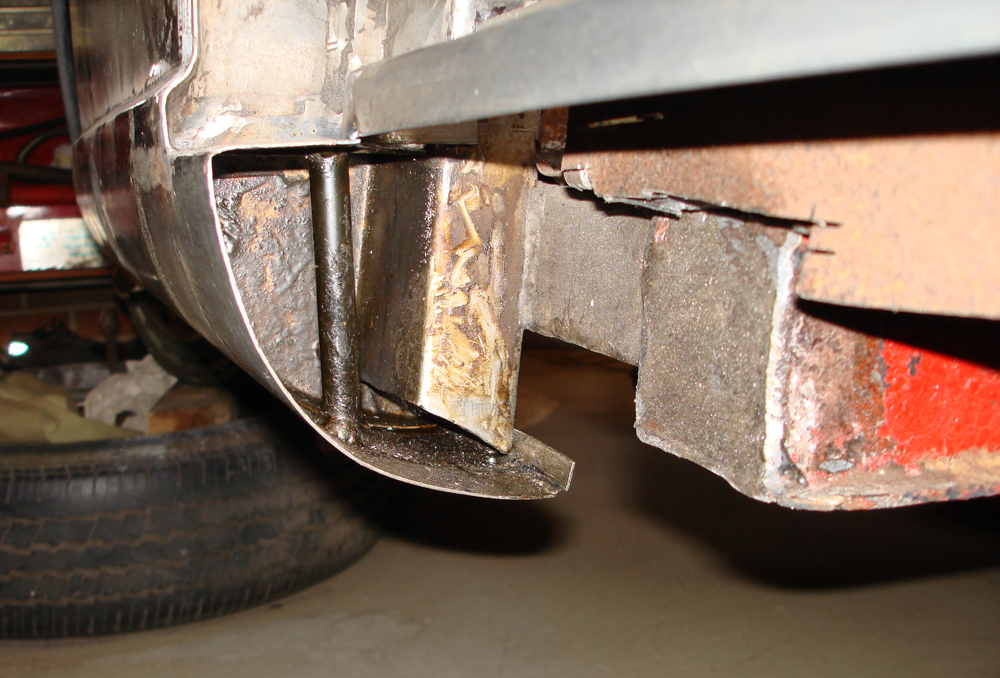

The front left A pillar with rusted areas removed. There were 3 layers of sheet metal in the pillar which created a rust trap.

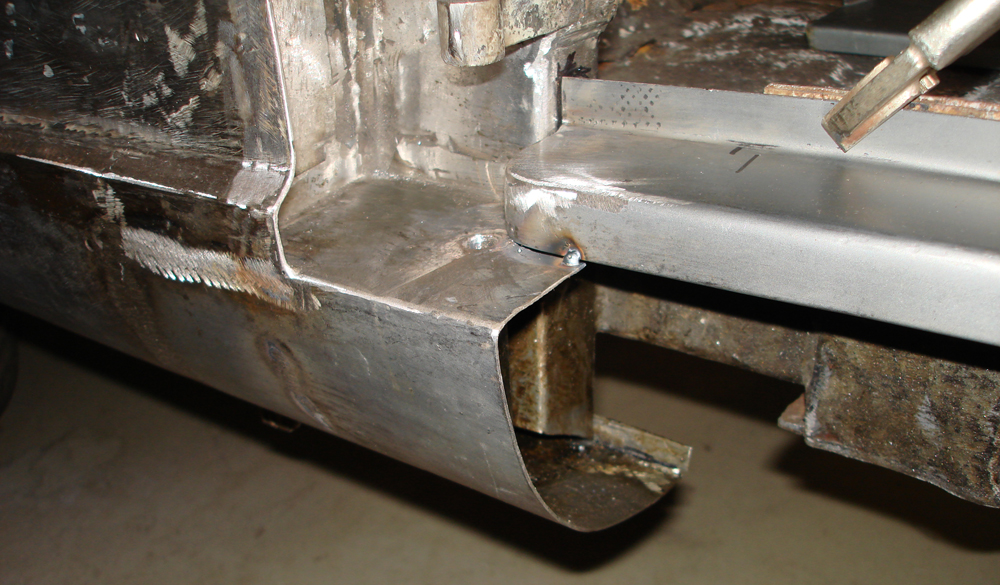

Repair of the pillar which is all replaced with stainless steel. The tube passing through the sill is as original so a rod can be passed through to knock out the lower door hinge pin. All of these areas are treated with a mixture of wax and fish oil to prevent rust re occurring.

The completed repair of the pillar.

Installation of the outer sill, once again the white spots are shrinks to bring the front wing into shape.

Repair of the left B pillar, once again stainless steel has been used, and the profile of the curved changed so that the pillar will not be in contact with the outer sill, as it was originally and created a rust trap between the two panels.

The left outer sill installed

Once again the left outer sill installed and trial fitting of the alloy lower trim

Left inner wheel arch, the wheel arch will not have the original closing panel following the outer panel, instead it will be a full radius with turned over edge to the outer panel that will be sealed after painting so that the rust trap around the outer panel wheel arch opening is eliminated.

Rear floor panel showing the edge to the outer panel that will be sealed after painting.

Holes added to the inner sill for access to the studs that will secure the alloy strip that runs along the car directly below the door opening.

Completed repair of the B pillar area with lead loading replaced.

The outer body finally completed, over 600 hours work by Jerry.

Another view of the completed body

Jerry Mlinaric with the completed body, an old school craftsman. Jerry is well known to the Austin Healey community in Australia, in the days when panels weren't available off the shelf Jerry made a aluminum front wing for a 100S by hand in a day.

And lastly, this is the remains pile of sheetmetal that has been replaced.

Page 8

Home