Release the

piston

Magnus Karlsson

Boras, Sweden

492karlsson@telia.com

Edited by Reid Trummel

Stuck pistons in the

brake calipers can sometimes become really stuck. The normal method to

"unstuck" them is to blow compressed air into either one of the holes for

the bleed nipple or into the brake pipe nipple. To do this, first make

sure that the other hole (the bleed nipple or the brake pipe nipple, whichever

one you're not using to blow in the compressed air) is blocked. Then insert

a piece of wood between the pistons in order to dampen the impact when

the piston releases.

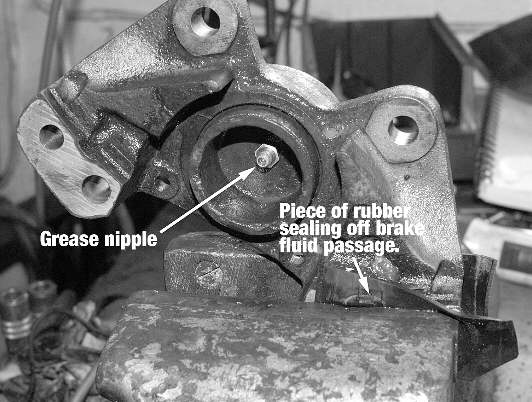

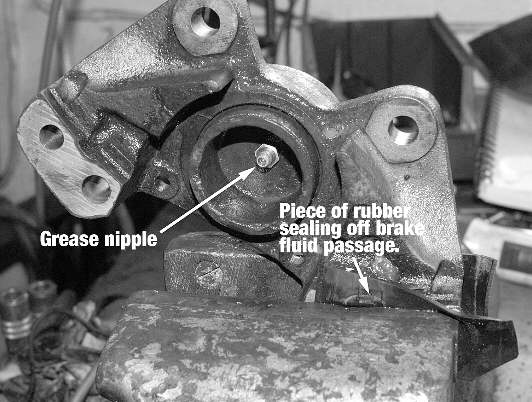

Piston that wouldn´t

let go eventhough grease was used through the bleed nipple hole.

If the compressed air

method is not successful, try the grease gun method. It works along the

same principles, but you fit a pointed end to your grease gun and hold

that pointed end very tight to one of the brake fluid holes in the caliper.

This method will exert a much higher pressure on the pistons than the compressed

air method will. However, if the pistons really are stuck, chances are

that you will not beable to keep the pointed end firmly enough against

the hole and thus the grease will leak out.

Tapping a hole in the

piston in order to fit a grease nipple.

Now is the time to become

"radical." First you split the calipers. This is something that many people

are afraid to do since it is stated in Girling manuals that this is strictly

forbidden. However, Girling gives no reason as to why this practice should

be avoided. I cannot take any responsibility for what can happen if someone

reads this article and decides to split his calipers, but I can say that

I have done it with many calipers and never had a problem. Myself, I prefer

this practice to scrapping calipers with stuck pistons. It also gives one

the opportunity to change the seal between the caliper halves, the condition

of which can leave a lot to be desired after 40+ years. It is important

to use a rectangular-section O-ring (flat, like metal washer) for this

as it has been manufactured to function in a brake fluid environment. An

ordinary O-ring (with a round section) may not be compatible with brake

fluid, since most of them are manufactured to function only with oil and

gas.

After your calipers are

split, you next drill a hole through the piston with a suitable diameter

drill, so that the hole can be tapped to fit a grease nipple (see photo).

Then you block off the brake fluid passage by clamping the caliper half

in a vice with a piece of rubber mat covering the passage. One of the caliper

halves is easy to clamp in the vice. In order to clamp the other half you

must use two of the caliper bolts as seen in the photo.

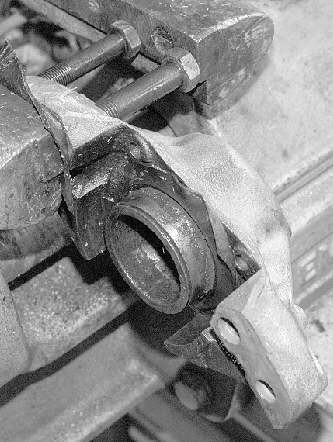

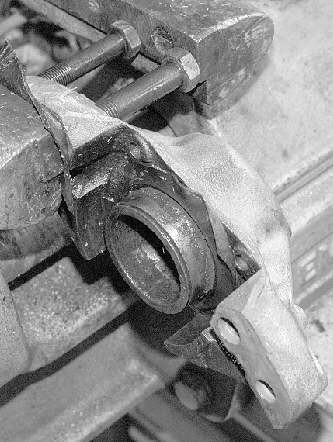

After your calipers are

split, you next drill a hole through the piston with a suitable diameter

drill, so that the hole can be tapped to fit a grease nipple (see photo).

Then you block off the brake fluid passage by clamping the caliper half

in a vice with a piece of rubber mat covering the passage. One of the caliper

halves is easy to clamp in the vice. In order to clamp the other half you

must use two of the caliper bolts as seen in the photo.

Caliper bolts used

so that the caliper half can be clamped in the vise.

Then attach your grease

gun to the nipple and start pumping it. You will find that the stuck piston

comes out very easily and in a very controlled way. I have yet to experience

a piston that will not release when subjected to this treatment.

After completing this

operation you will of course have to replace the pistons, the seals and

the dust seals. I recommend that you fit stainless pistons as they are

available for both types of calipers used on Healeys.

Restored caliper half

fitted with new seals and stainless piston. Please observe the correct

square section O-ring, top left corner.

home