ROUND THE BLOCK

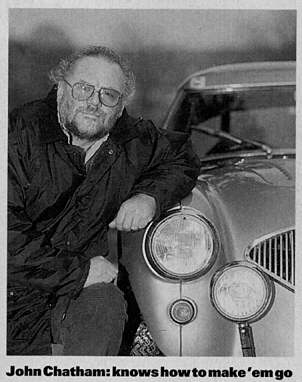

Big Healey guru John Chatham has put together the

ultimate 100/4 using high-tech engineering and a bullet-proof

engine. Mick Walsh prepares for some sideways action

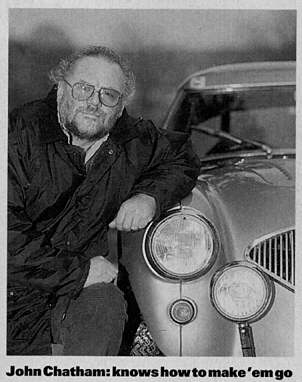

It's difficult to imagine the hearty Healey guru John Chatham

as a 12 year old pedalling down the Gloucester Road. But he still vividly

remembers the day he fell in love with a Healey 100/4: "I was a regular

fixture with my nose pressed against Henlys' showroom window, ogling a

glorious red 100/4 revolving on a plinth. I'm sure its seductive curves

induced my first orgasm," John recalls bursting into laughter.

Close to 40 years later, the bristol-based specialist

is almost as enthusiastic about his first Healey love, having recently

turned his attentions to a pretty 'four' after several decades of setting

the pace on track and stage with his trusty 3000 racers DD 300 and GRX

884D: " My first Healey was a 100/4 and I won awards in just about every

form of motor sport- rallies, driving tests, sprints, races and hill climbs,

and then drove it to work again on monday morning. We'd shave lumps off

the cylinder head to go quicker, but at the circuit it was simply aeroscreens

and taped headlights. Its all-round capability always struck at the back

of my mind."

That was back in 1962; it wasn't until last year that

Chatham turned his attention again to the 100/4: " I knew it would never

have the legs on the 3000 for the circuit, but for events like the Classic

Marathon, I always considered it a more nimble car. The long stroke four

has immense torque which provides effective punch when you really need

it - particularly for hairpin bends. My goal was to prove the 100/4 could

be quicker than the 3000."

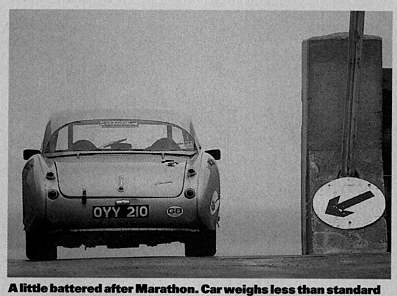

Last year on the Marathon, John really proved his point.

On the second timed stage in Belgium only the 'flying finn', Timo Makinen

in a Mini Cooper was quicker. First time out of the box the 100/4's potential

was proven, although the rest of the event turned out to be a disaster

for Chatham's immaculate silver machine. On the first stage in England

he holed the sump, and later in Germany a clutch hydraulic failure put

him out of the running.

John's project - the development of the ultimate 100/4

- is essentially based around the 2.5 litre Austin diesel engine as used

in the FX4 London taxi. Geoff Healey had considered this proposal many

years ago when Austin Healeys were still in production.

The Austin diesel engine has a bullet-proof block and

crankshaft to withstand the 22:1 compression ratio necessary to run a compression

ignition engine and therefore overcome the inherent weakness of the original

A90 petrol engine. Both Dave Jeffery of SC Austin Healey Parts and John

Chatham were keen to see if Geoff's original proposals could be made to

work. Design and development started seriously at the beginning of 1990.

It was decided to retain the shorter stroke of the diesel

engine (101.5 mm compared to 111mm for the A90) in order to allow a higher

revving engine and to avoid alterations to the substantial crankshaft.

This is a nitrided EN40B forging with larger bearing sizes than the original.

The block was over bored into the water passages, and then linered using

specially made thick wall liners. These were then bored to virtually 91

mm for a capacity of 2615cc ( compared with 2670cc originally ). Ford Sierra

Cosworth pistons were used and new con rods specially made ( the diesel

rods being much too heavy for a high revving engine).

The top of the diesel block has a multitude of studs,

non of which lined up with the holes for the petrol cylinder head. Two

studs were very close and one of SC's new 100/4 alloy heads was machined

specially to suit these. The rest of the studs in the block face were blanked

off and the remainder of the studs required to fit the head specially drilled.

All of the studs were specially made in EN24 heat treated to 80 tons to

enable torquing up to 125 lb ft. Because of the engine family resemblance,

the pushrod holes and combustion chambers lined up well enough.

SC had previously spent a considerable a considerable

amount of time and resources with the Institute of Noise and Vibration

at Southampton University. This work had been to overcome various mechanical

failures caused primarily by crankshaft and camshaft torsional vibrations

when the six-cylinder Austin Healey engine was producing large amounts

of power at high revs. Now it was the turn of the four cylinder.

Research with the six-cylinder engines had shown that

only static testing would be required with the four-cylinder diesel crank.

Fortunately, the bullet-proof assembly passed with flying colours, with

the comment that there could be a serious vibration period at 14,000 rpm!

Not a problem.

SC now had a bullet-proof petrol engine but nowhere to

put the distributor ( diesels don't use them ). The distributor probably

could have been fitted under the inlet and exhaust manifold but this was

not considered a viable option. Thus the problem was solved by fitting

the distributor where the injection pump was fitted on the diesel engine.

This meant using the diesel's timing chain layout but this was a heavy

triple chain arrangement designed to run a maximum of about 3500 rpm. A

completely new double chain layout was designed and made using modern dampers

together with a specially designed oil-fed tensioner. A modified VW Golf

distributor is used, pointing backwards from the timing cover under the

dynamo.

Two 2 inch SU carburettors are used, together with a

very special large bore exhaust manifold. The camshaft is ground to a profile

similar to that used on the last of the works six cylinder competition

cars. About 150 bhp has been recorded at the rear wheels, probably about

170 bhp at the flywheel, at around 6000 rpm. As the engine is quite happy

running up to 7800 rpm there is obviously a lot more development possible.

Larger carburettors ( Weber probably ) together with a much more extreme

camshaft will release a lot more horsepower.

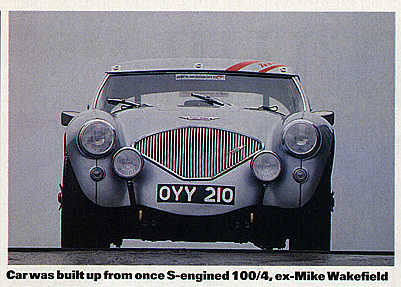

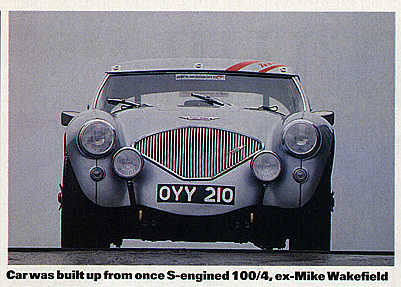

Once dave Jeffrey had completed development of the engine,

John set about preparing a car to use the new levels of power. He had been

saving just such a project for over 20 years, having previously acquired

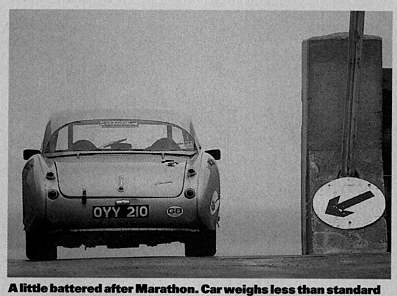

a well known alloy 100/4 once club raced by Mike Wakefield. Registered

OYY 210 and fitted with a genuine 100S engine, John had made overtures

that he'd be interested in acquiring it if it were ever sold.

Unfortunately he was on holiday when the owner made contact

and by the time john returned the prized engine had been sold separately,

but the rest of the car was soon back in Bristol. Over the years the car

has been pillaged for other restorations but the alloy shroud, doors and

boot were an ideal basis for the new project.

The suspension specification is simple: heavier front

anti-roll bar and stiffer spring rates than standard, and heavy duty shocks

all round. The bushing and locating points are all standard, while a touch

of negative camber is employed at the front. Front discs are Girling MK1

spec with DS11 pads which have always proved effective enough hauling up

the works 3000s. A twin plate competition clutch helps keep the massed

weight down on the crank. Tulip straight cut gears and a competition 22

per cent overdrive provide an ideal set of six ratios to dial in the power,

with the switch mounted on a standard BN2 gear lever.

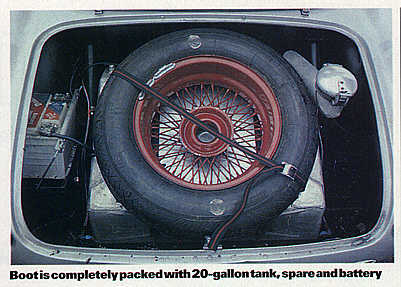

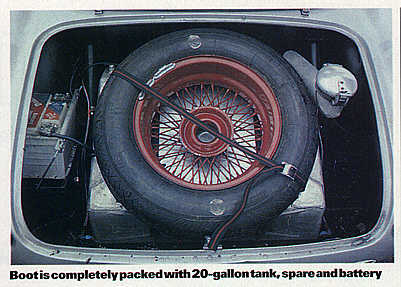

A 20 gallon tank, 12-volt battery and spare wheel pack

out the boot and leave next to no luggage space. The six point roll cage

is cleverly disguised by a handsome alloy hard top, while the lower front

cross bar proved ideal to mount Halda, navigator light and Speedpilot.

The top also hides the non period high backed Kevlar rally seats but no

sidescreens are fitted as John prefers to enjoy fresh air conditioning,

and resents restricted vision - an important consideration as he tends

to spend most of his driving time sideways. The instrumentation is as stark

as a standard 100/4, but with the installation of a modern rev counter.

The exhaust is an inspired design by John, who was not

keen on suffering a noisy under door exit or leaving the system on the

road at the first stage. A slightly longer inlet manifold flows into a

large diameter main pipe which is strapped up high to the chassis. The

rear shroud and crossmember have been cut away to gain extra clearance

and, combined with protective skids, the system survived intact after the

demanding conditions of the Marathon. Quite an achievement for any full

length Healey system.

The cars weighs in at 960 kgs compared to 987 kgs of

the standard car, but that's still heavier than the 100S. As with most

competition projects and event deadlines, the preparation of OYY 210 ran

out of time for the Marathon. John would have preferred a longer shakedown

but the finished car looked superb in Mercedes silver with red wires at

Tower Bridge for the start. A holed sump on the first stage in England

was gamefully patched with the help of the unipart service barge, but after

setting a scorching pace through Belgium, those clutch hydraulics failed

in Germany. In the pouring rail John and loyal co-driver Ken Bartram took

the gearbox out at the side of the road, without the co-operation of a

miserable German garage proprietor who refused to open up and allow the

use of his ramp. Although by then well out of the running, the 100/4 continued

to prove it's stamina and potential on the event. The run back with a pair

of 3000s also provided an interesting mpg test. Using accurate mileage's

measured on the speedpilots, the 100/4 returned a healthy 28 mpg compared

to a 23 mpg best by the six.

True to the 100/4 experience, the interior leaked like

a colander during downpours, soaking the driver and navigator. Under bonnet

heat is still a continuing problem, particularly in traffic: the radiator

is already extensively ducted by heat outlets are still not enough. Fuel

vaporization is a big problem, particularly when waiting for the start

of a special stage. The exhaust manifold is already wrapped in asbestos,

but the car continues to stutter when the light goes green. A fuel return

system could be the answer in an attempt to keep the gas cool.

John is determined to return and is also considering

a team of 100/4s for next year's Mexican Carrera PanAmerican retrospective,

but since the Marathon disaster OYY 210 has fulfilled all his ambitions

on the circuits. At Mallory Park for a Healey Club Championship round John

debuted the 'diesel', psyching up arch-rival Dave Hardy about his "secret

development engine". Hardy has been campaigning 100/4s for many years,

so holding him off to take second overall first time out was a proud achievement.

The heated 10-lap tussle saw the two cars just 1.5 secs apart at the flag.

Constant lap times of 48 secs were only 2 secs off Chathams Mallory best

with DD 300.

Other highlights of 1991 were the Last Healey race of

the season at Castle Combe when, in a father and son challenge against

the Welch and Hardy clans, Joe Chatham in his first ever race came home

sixth with OYY 210. Dad couldn't catch Dennis Welch but Joe headed the

other sons to take overall glory for the Chathams. Next came a visit to

the isle of white for the traditional Healey Club weekend which provided

the opportunity for Geoff Healey to test the car. He returned after a brisk

drive, and in his usual guarded manner just hummed and puffed on his pipe,

without forwarding any definite judgement. However, about half an hour

later he returned and complimented John that he thought "the engine was

fantastic". He said it immediately reminded him of x224, the modified 100S

chassis that the Cape works fitted with a Ferrari 2.5 litre, four cylinder

F1 engine. High praise for the Austin diesel based unit.

As for John, well he'd still rather drive a 3000 on the

circuit - namely his treasured evergreen racer DD 300: " I'm a sucker for

its ultimate grunt, but the 100/4 is the best all round Healey. It's so

easy to drive and the new engine has definitely cured the lazy response

of the four without loosing that desirable low down torque. This one still

really thumps from low revs. Everybody still considers them the pretty,

no go Healey that could be licked by a TR, but we've certainly woken this

one up. All the effort of the development has been worth it just to prove

that. And I enjoy driving it more than GRX", John concluded. And for anyone

who understands John's long affection for his 3000 rally warrior, that

is quite a conversion. Driving The Chatham Healey 100/4

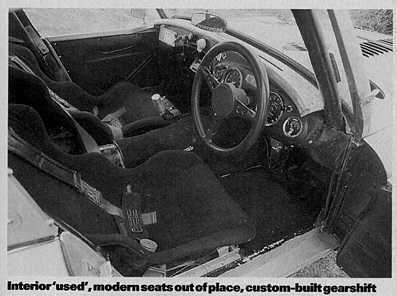

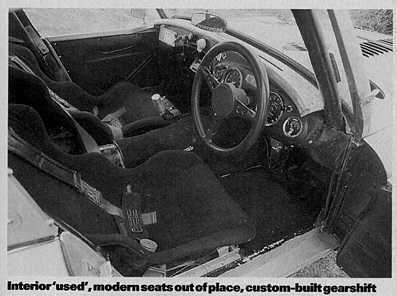

To my mind the 10/4's cockpit lacked sporting charisma at

the best of times. Gerry Coker's original styling sketches had a flashy

American look, but the end result was basic and simple. Chatham's warrior

is functional to the last with roughly cut carpets and black satin paint

finnish on the dash and panels. Already the worn and scratched interior

indicates the tough action this pretty car has already encountered.

Driving The Chatham Healey 100/4

To my mind the 10/4's cockpit lacked sporting charisma at

the best of times. Gerry Coker's original styling sketches had a flashy

American look, but the end result was basic and simple. Chatham's warrior

is functional to the last with roughly cut carpets and black satin paint

finnish on the dash and panels. Already the worn and scratched interior

indicates the tough action this pretty car has already encountered.

Apart from the modern tacho, standard dials straddle

the thick small leather rimmed wheel, while a large orange oil pressure

warning light sits dead centre. Spread across the normally bare curve of

the dash to the passenger's door are indicator knob, master switch and

extra horn, while the Halda rally equipment is hung underneath on the rollover

bar brace.

The gearstick is crooked well back to the driver's side

and topped with a spun aluminium knob cleverly incorporating the overdrive

switch. The plain door pockets are the only storage space, while inside

is a cable door pull which aids rapid navigator exit to stop the clock

at the end of a special stage.

The modern high backed rally seats are as tight fitting

and as superbly supportive as you would expect. But in a fifties car, I

can't forgive their unsuitable image, although thankfully the hard top

hides them away. Strapped up in the harness, the driving position is still

typically Healey - seated flat and low with legs straight and elbows bent

for the close wheel. There's little to get nostalgic about in this gutted

cabin as supreme function is the primary concern. So down to business:

turn the centre ignition key, press the starter button and after a couple

of churns the engine catches, sounding gruff and lumpy, more like a rally

Escort than sporty Austin. Flex your right foot and the engines reformed

response is instantly apparent, so much more revvy than the Agricultural

fours I've previously encountered.

Out on the Road and opened up, the engine is little short

of sensational, particularly in such responsive chassis. It takes a while

to adjust to the extra revs in the 100/4 - changing up at 5500/6000 rpm

rather than the standard 4000 rpm - but little of the engines low-down

urge has been lost with the extra flexibility. But from 4000 rpm you really

feel the power delivery as it spins to unheard of rev limits for such a

humble truck engine. With close-cut ratios, the normally sluggish BN2 gear

change is no handicap, and up to 60 mph, it could shave at least a second

of a 100S. John reckons she's good for 7 secs, but the engines wide power

spread is it's big appeal. The purists will decry its new performance as

erroneous to the true character of the 100/4, but I bet Geoff Healey wished

he'd pursued the development of the diesel after he'd sampled Chathams

racer.

The combination of the direct steering, the bite of the

improved brakes, the neutral chassis balance and the rapid six-speed with

its trigger overdrive ratios inspires confidence. Even on the slippery,

desolate roads down by the Severn estuary, this superbly sorted machine

was irresistible. Dialling in the ratios with the engine singing at the

top end, it feels and sounds proudly exotic. Later, watching John play

to the photographer, powering through the turns and flicking the tail out

on the damp roads, the exhaust rasp sounded more Moderna than Warwick.

With John's enthusiasm for the project, it's a sound we shall hear regularly

setting the pace on stage and track - when he can keep the wheels on the

ground........

Mick Walsh

Article written by Mick Walsh and published in the March 1992

edition of Classic and Sportscar magazine

Home