THE WIRE TRICK

by Mr. Finespanner®

“The Wire Trick” is something I have heard mentioned

in various places, but I don’t know that it has ever been the topic of

a Healey tech article, hence this humble effort.

In the factory manual, the technique described for refitting

an overdrive to a Healey gearbox calls for the adapter plate to be bolted

onto the back of the gearbox and then the overdrive added by compressing

the eight clutch springs, using the two long studs on the sides.

With this method, the overdrive is held captive and the gearbox is lowered

onto it. All well and good, but it can be a pain in the butt humping

the gearbox up and down, and the process can be time consuming. There

is an easier way.

The next time you are involved in an OD R&R, try this.

Take off the overdrive by separating the adapter plate from the gearbox.

This leaves the adapter plate still bolted onto the OD, with those bothersome

clutch springs remaining compressed in place, and no longer a factor in

the refit. The gearbox should be positioned standing upright on a

couple 2 X 4's, and the OD comes off by yanking it straight up and off

the mainshaft. Be careful not to disturb the mainshaft rear bearing,

as the adapter plate is what holds this bearing in place in the gearbox

case. If the box is standing on the bellhousing this is not usually

a problem, since gravity tends to keep things situated. There also

should be two large, thin bearing shims between the adapter plate and the

gearbox case. Keep track of these.

The next time you are involved in an OD R&R, try this.

Take off the overdrive by separating the adapter plate from the gearbox.

This leaves the adapter plate still bolted onto the OD, with those bothersome

clutch springs remaining compressed in place, and no longer a factor in

the refit. The gearbox should be positioned standing upright on a

couple 2 X 4's, and the OD comes off by yanking it straight up and off

the mainshaft. Be careful not to disturb the mainshaft rear bearing,

as the adapter plate is what holds this bearing in place in the gearbox

case. If the box is standing on the bellhousing this is not usually

a problem, since gravity tends to keep things situated. There also

should be two large, thin bearing shims between the adapter plate and the

gearbox case. Keep track of these.

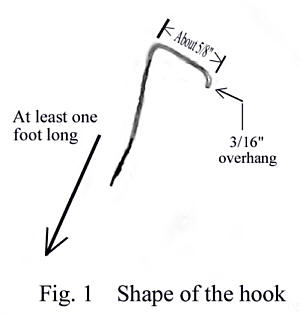

The Wire Trick comes into play during the refitting process.

With the factory book method the OD oil pump plunger is held down by reaching

a shaped tool of some kind in between the OD and the adapter plate and

pushing down on the plunger. In this way the oil pump cam can slide

down the mainshaft and into position over the plunger roller. If

the adapter plate is bolted to the OD that gap is not there to reach through,

so a piece of wire is used instead. It must be reasonably heavy without

going into coat hanger range. What I have found works best is regular

ol' NAPA 16 gauge mechanic's safety wire. It is stiff enough to hold

but flexible enough to release when you want it to. A piece at least

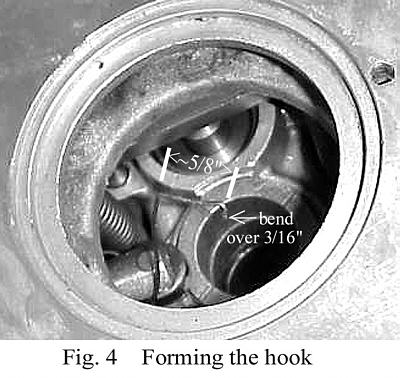

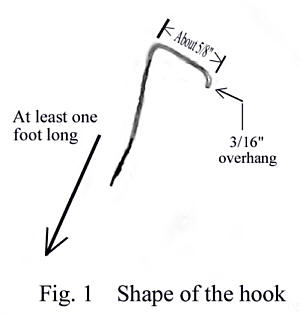

a foot long is required, and the end is formed into a hook, which engages

the top of the plunger and holds it down (see Fig. 1).

The Wire Trick comes into play during the refitting process.

With the factory book method the OD oil pump plunger is held down by reaching

a shaped tool of some kind in between the OD and the adapter plate and

pushing down on the plunger. In this way the oil pump cam can slide

down the mainshaft and into position over the plunger roller. If

the adapter plate is bolted to the OD that gap is not there to reach through,

so a piece of wire is used instead. It must be reasonably heavy without

going into coat hanger range. What I have found works best is regular

ol' NAPA 16 gauge mechanic's safety wire. It is stiff enough to hold

but flexible enough to release when you want it to. A piece at least

a foot long is required, and the end is formed into a hook, which engages

the top of the plunger and holds it down (see Fig. 1).

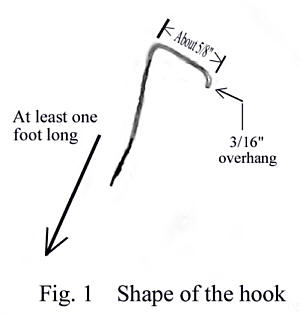

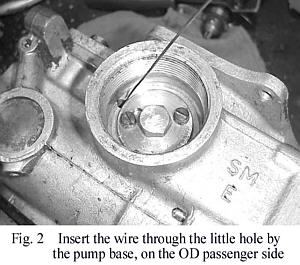

Using a suitable tool, remove the large brass plug from the

bottom of the OD and take out the cup-shaped strainer screen and magnets.

There is a little hole on the body of the OD unit that the pump base partially

covers, on the passenger side. Feed the wire up through this hole

(see Fig. 2) and on the other side urge it towards the center of the unit,

so that the tip of the wire passes between the springs and pump plunger.

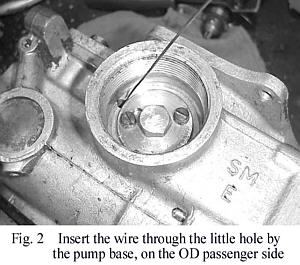

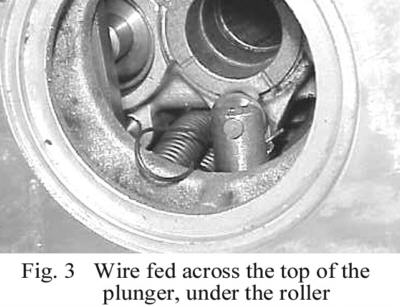

Work the wire up until you have a couple inches to play with, then loop

it sideways and feed it under the plunger roller and across the top of

the plunger using a long pair of needle-nose pliers (Fig. 3). Bring

out an inch or so beyond the edge of the plunger to make the hook with.

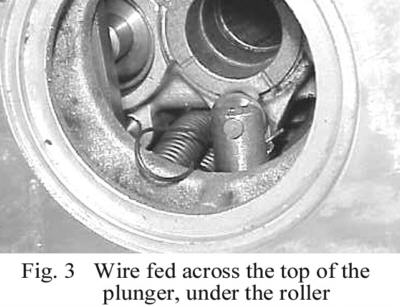

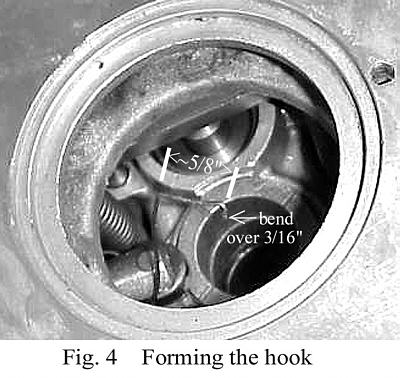

The hook is just two 90° bends, one over the

plunger and a small locking overhang on the end

Using a suitable tool, remove the large brass plug from the

bottom of the OD and take out the cup-shaped strainer screen and magnets.

There is a little hole on the body of the OD unit that the pump base partially

covers, on the passenger side. Feed the wire up through this hole

(see Fig. 2) and on the other side urge it towards the center of the unit,

so that the tip of the wire passes between the springs and pump plunger.

Work the wire up until you have a couple inches to play with, then loop

it sideways and feed it under the plunger roller and across the top of

the plunger using a long pair of needle-nose pliers (Fig. 3). Bring

out an inch or so beyond the edge of the plunger to make the hook with.

The hook is just two 90° bends, one over the

plunger and a small locking overhang on the end

(see Fig. 4).

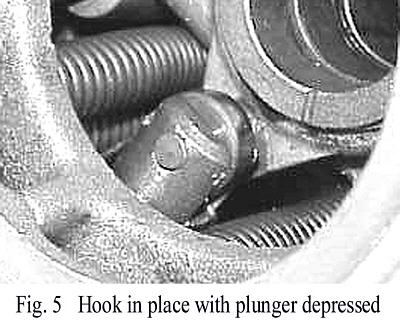

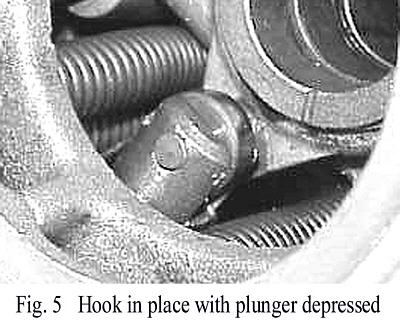

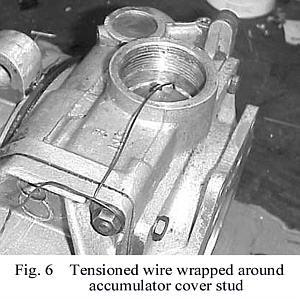

Once the hook is made, pull on the other end of the wire

to draw the hook down in place on top of the plunger, guiding the tip with

the needle-nose pliers. Make sure the tip is curled down along the

plunger to hold the wire in place when the plunger is depressed. Then,

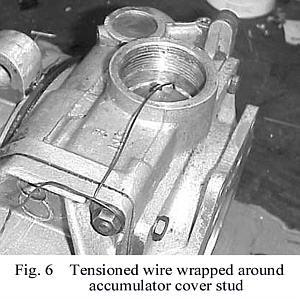

keeping tension on the loose end of the wire, use a long beefy screwdriver

to press the plunger down. Do NOT use the wire to pull the plunger

down! Hold the plunger all the way at the bottom of it's stroke with

the screwdriver and then pull the wire tight and wrap it around something

convenient, like the bottom front stud on the accumulator cover

Once the hook is made, pull on the other end of the wire

to draw the hook down in place on top of the plunger, guiding the tip with

the needle-nose pliers. Make sure the tip is curled down along the

plunger to hold the wire in place when the plunger is depressed. Then,

keeping tension on the loose end of the wire, use a long beefy screwdriver

to press the plunger down. Do NOT use the wire to pull the plunger

down! Hold the plunger all the way at the bottom of it's stroke with

the screwdriver and then pull the wire tight and wrap it around something

convenient, like the bottom front stud on the accumulator cover

(Fig. 5 and Fig. 6). If you have done everything

right and the gods smile upon you a bit, the plunger will be parked down

out of the way of the cam and you are ready to put the OD back on the gearbox.

Another vital part that the adapter plate holds in place

in the gearbox is the layshaft, so it is imperative that the overdrive

go DOWN onto an upright mainshaft, and not the other way around.

Leave the bellhousing standing upright on the 2 X 4's and lower the OD

on. If you pick the gearbox up with the mainshaft pointed down and

the adapter plate off the layshaft can fall out, which means you have to

take the gearbox apart to get it back in. Not fun. Reposition

the two bearing shims on the race using a little grease to hold 'em in

place. Make sure the little locating peg in the bearing housing ring

is turned so that it correctly indexes into the divot in the adapter plate.

Another vital part that the adapter plate holds in place

in the gearbox is the layshaft, so it is imperative that the overdrive

go DOWN onto an upright mainshaft, and not the other way around.

Leave the bellhousing standing upright on the 2 X 4's and lower the OD

on. If you pick the gearbox up with the mainshaft pointed down and

the adapter plate off the layshaft can fall out, which means you have to

take the gearbox apart to get it back in. Not fun. Reposition

the two bearing shims on the race using a little grease to hold 'em in

place. Make sure the little locating peg in the bearing housing ring

is turned so that it correctly indexes into the divot in the adapter plate.

Then put a couple of thin (~ 3/16") pieces of wood about

two inches long on the top of the gearbox case at opposite edges.

A 2" chunk of paint stirring stick works well. Now, with the annulus

splines aligned and the mainshaft rotated to the right spot, lower the

OD down into place. The thin wood bits will keep it from going all

the way home and leave the edge of the adapter plate high enough to get

nuts and lock washers on the case studs. Once all the nuts are started

onto the studs you just remove the wood spacers, slide the OD all the way

down, and torque the nuts. Undo the wire end from where it is wrapped

and hold it in the jaws of the long needlenose pliers over the opening

for the strainer screen. Roll the pliers smoothly and firmly to wrap

the wire around the jaws and draw the tip back over the end of the plunger

and down out through the hole. It is important to do this smoothly

without jerking, or else the wire can break off inside the OD. Once

the wire is out, refit the screen, magnets, and plug, and you're back in

buisness

Then put a couple of thin (~ 3/16") pieces of wood about

two inches long on the top of the gearbox case at opposite edges.

A 2" chunk of paint stirring stick works well. Now, with the annulus

splines aligned and the mainshaft rotated to the right spot, lower the

OD down into place. The thin wood bits will keep it from going all

the way home and leave the edge of the adapter plate high enough to get

nuts and lock washers on the case studs. Once all the nuts are started

onto the studs you just remove the wood spacers, slide the OD all the way

down, and torque the nuts. Undo the wire end from where it is wrapped

and hold it in the jaws of the long needlenose pliers over the opening

for the strainer screen. Roll the pliers smoothly and firmly to wrap

the wire around the jaws and draw the tip back over the end of the plunger

and down out through the hole. It is important to do this smoothly

without jerking, or else the wire can break off inside the OD. Once

the wire is out, refit the screen, magnets, and plug, and you're back in

buisness

Contact Mr.

Finespanner

Home