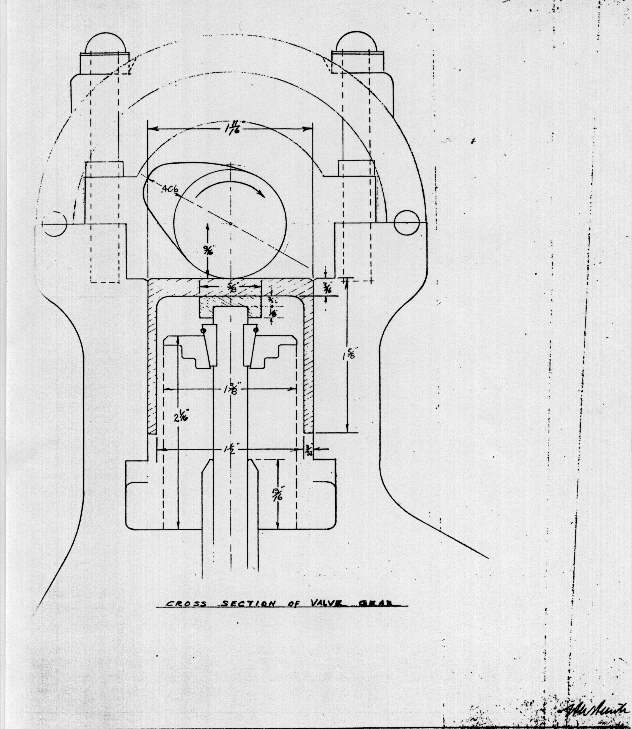

These tappets appear to be running directly in the head. However many aspects of the design are not shown in the drawings including the camshaft bearings ( if there were any ) so it is dangerous to make too many assumptions! It should also be noted that materials of construction are rarely mentioned an exception being one of two camshaft drawings which calls for "Atlas SPS245".