Resistance welding plays a most important part in the body building industry and a prominent feature of any mass production plant is the lines of more or less elaborate automatic welding machines which unite numerous sheet steel panels and sub assemblies into the typical unit construction body shell. Other modern welding methods, however, are likely to be more applicable where the scale of operations does not justify the installation of expensive and complex tooling.

Small-scale production

It is not only the cost of the plant and equipment

that prevents large resistance welding machines from being used in relatively

small scale production. Matched press tools for body panels are so

costly that enormous production runs are required to amortise them.

Hand panel beating, therefore, is employed for small quantities, while

rubber press tools, requiring only a shaped male die instead of an intimately

matched pair of tools, can cope economically with intermediate quantities.

Light alloys, on account of their ductility and ease of working, are widely

used in conjunction with these forming methods. Furthermore, with

the class of car commonly built in such limited numbers, weight saving

is often of some importance.

Resistance welding is unsuitable for use on aluminium alloys, and an attractive alternative is inert gas shielded arc welding. This method is being increasingly employed in plants concerned with the production of specialist and high performance cars, and also for goods and passenger vehicle bodywork. Apart from the main advantage of the process, the prevention of oxidation of the heated metal, it provides clean, smooth and strong welds and has an easily controlled underbead. These are useful features where finish is important, as it is in these sections of the motor industry.

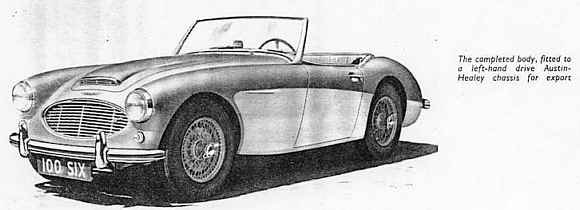

A good example of the class of car to which

the above considerations apply is the Austin-Healey sports model.

While this car is a popular representative of its type, it is designed

for a relatively limited public and cannot be produced in anything approaching

the numbers usual for the typical family saloon. The body shell is

composite steel and light alloy structure, manufactured at West Bromwich

by Jensen Motors Ltd. This firm has a long connection with specialist

car production, and has acquired wide experience in the production methods

economically applicable to limited outputs.

To provide the stiffness essential for stability at high speeds, the chassis frame is a fabricated steel structure of great depth, additional strength being provided by the body side panels which are also of steel. The remainder of the shell, comprising front and rear ends and top decking, is generally of 16 S.W.G. aluminium-manganese alloy to B.S. 1470 N.S.3. This combination of materials results in a very favourable overall strength:weight ratio.

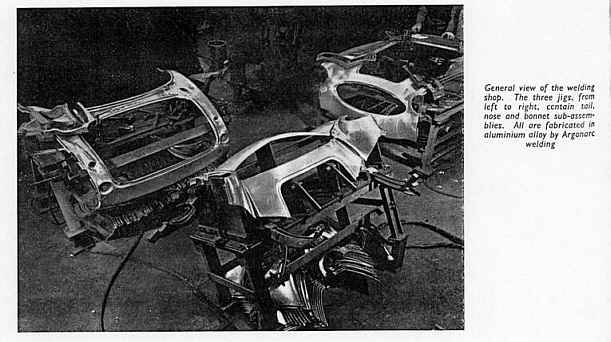

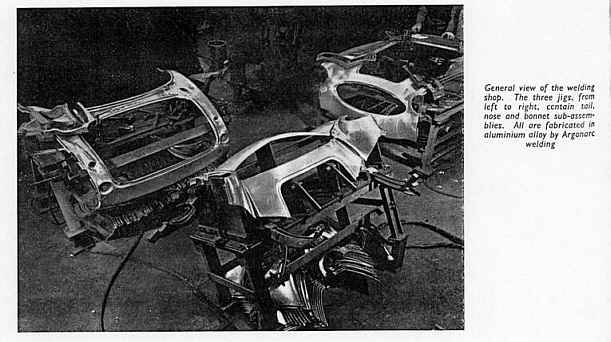

Extensive use of aluminium

In the complete body, the light alloy structure

comprises two large one piece sections, forming respectively the whole

of the upper surfaces before and behind the cockpit. To simplify

assembly and tooling, each main panel is built up by welding together a

number of smaller sections,. The general view of the welding shop

shows the breakdown of sub-assemblies quite clearly. In the foreground

the nose-shell section, comprising four small and simple pressings, is

mounted on a jig. At the left, a complete tail section, built up

from seven separate parts, is ready to be removed from its jig. At

the right, the nose-shell section is about to be welded to the bonnet-top

structure, which is itself made up from three sections.

This method of assembly reduces both the size

and the complexity of the formed parts, most of which receive their basic

shaping in a rubber-platen press. Re-entrants, flanges and small

cut-outs are formed by hand panel-beating in special jigs, Extremely

accurate jigging is called for to obtain the required accuracy, and a high

standard of welding is demanded to ensure that the panel joints are invisible.

That these aims are attained is evidenced by the excellent finish of the

completed body.

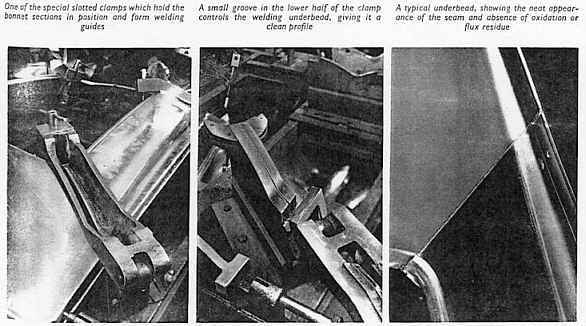

Probably the most important factor affecting appearance is the choice of Argonarc welding for all the panel joints. The advantages of this method from the point of view of protection of the light alloy material from oxidation is well established. What is equally important in this application is the very small amount of distortion which results from the cooling effect of the argon gas shroud, and the speed with which welding can be effected. Much thought has been given to the design of the jigs to clamp the panels firmly in alignment, to maintain the correct spacing between the joint faces, and to control the welding underbead.

Welding jigs

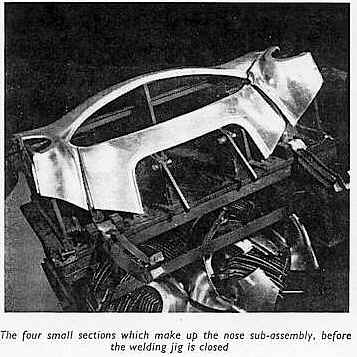

The jig for the nose assembly, with the individual

panels in place, is illustrated. The clamps, which are specially

shaped to form welding guides, can be seen in the open position.

When they are closed, they automatically position the panels to leave a

maximum weld gap of 1/16 in. One of these clamps in the open position

is shown in detail, this time as part of the jig for the bonnet top assembly.

The upper half of the clamp is slotted along the centre line, giving access

to the upper surface of the panels for a width of about ¼ in on

each side of the joint line. The sides of the slot are chamfered

to provide easy access for the welding torch. Penetration is controlled

by a semi-circular groove formed in the lower, fixed half of the clamp.

This ensures a net underbead, about 3/16 in wide and 1/8 in deep.

Since all the proud metal on the outer, visible surface of the panel is

ground away to provide a smooth finish, the underbead forms a reinforcement

to the joint. The clean appearance of the underside is well shown

in the view of the reverse side of a joint in the bonnet top panel.

No post-welding treatment of any kind is required.

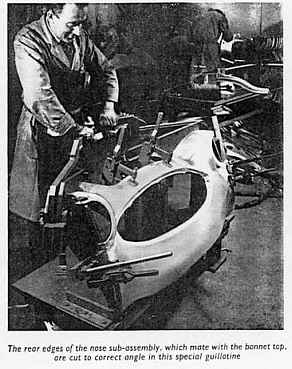

This illustration also gives some idea of

the complete lack of distortion in the light-gauge material. Reference

has been made to the importance of correct alignment of the sub-assemblies.

One of the ways in which this attained is shown in application to a completed

nose section, subsequent to welding and smoothing down the top beads.

Before it is mated to the bonnet top panels, the upper rear edges must

be carefully shaped to the correct angle. This operation is carried

out in a simple trimming jig. The nose section is clamped in a fixture,

resembling the welding jig in which it was assembled, and two large shear

blades are brought down on the rear edges to cut a clean, accurately positioned

face ready for welding. In the same fixture, the two levers at the

front are manually operated to punch a hole in the flange at each side

of the panel for its eventual attachment to the chassis structure.

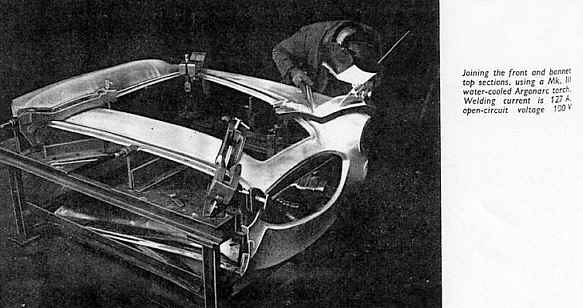

The final stage in the fabrication of the large front panel consists of

welding the nose section to the bonnet top section in a large jig built

on similar principles to the others. Welds are then ground down and

the seams are smoothed by hand tools, as shown in the illustration of an

operator finishing one of the longer welds between the two parts.

Electrical equipment

There are several points of interest in the welding technique and in the equipment used, which is of the latest type manufactured by the British Oxygen Co. Ltd. As is usual in the Argonarc welding of aluminium alloys, alternating current is employed. The reason is that the electrode-negative direct current, which gives efficient heat transfer to the work, the well known scavenging effect on the refractory oxide film is absent. Electrode-positive direct current, on the other hand, while providing the necessary oxide removal function, concentrates most of the arc heat at the tip of the tungsten electrode. With the high thermal conductivity of aluminium, this results in shallow penetration and low speed, as well as introducing the danger of contamination from the molten electrode tip.

Current is supplied to each pair of torches

by a Quasi-Arc ACP 2 300 transformer welding set, which can supply 300

A simultaneously to each torch. High frequency units are inserted

in each circuit to provide instantaneous re-iginition of the arc at the

zero point in each half cycle, and to ensure automatic initial ignition

without contact between electrode and work. This device consists

essentially of a spark-gap oscillator which superimposes a train of high

frequency oscillatory voltages on the main 50 c s supply, phased to milliseconds,

sufficient to re-establish the art without the need for an excessively

high arc voltage.

Inherent rectification of the welding supply

in the arc, which gives rise to an undesirable D.C. component, is countered

by including in the circuit a D.C. suppressor unit, consisting of a bank

of series capacitors which effectively block the direct current.

By ensuring that the electrode-positive half-cycle will be as long as the

electrode-negative, efficient scavenging of the refractory film is ensured.

The illustration of the welding operation uniting the nose and bonnet-top sections shows the typically oblique angle at which the 1/8 in. Alda pure aluminium filler rod is held at the leading edge of the advancing weld pool. The torches are of the Mk 111 water-cooled type, water and argon flows being controlled through an economizer unit on a bench. When the torch is not in use, it is hung on a small hook which automatically closes both the argon and the water valves. The open-circuit voltage is 100V, and each torch takes 127 A, under which conditions the average welding speed is about 10in. min. There is a total of about 13ft of welding in each complete set of panels. The average weekly output of complete units is about 125, which represents a very creditable figure when the time required for handling is taken into account. Argon is fed at 12 to 16 cubic ft per hour, the consumption being very modest at 300 cubic ft per week, or just over 2 cubic ft per body.

Finishing details

One interesting point in connection with the

assembly is that, on some of the panels, flanges round openings must be

hammered flat over a short distance to allow the part to lie evenly in

the jig. It is not possible to weld right to the end of the

joint because the clamp is in the way. In such cases, the joint is

completed after removal from the jig, using an ordinary oxy-acetylene torch,

aluminium filler rod and Alotectic flux. The extra heat from the

use of the flame has been found to have a useful annealing effect which

eases the subsequent operation of restoring the flange to its original

contour by panel-beating.

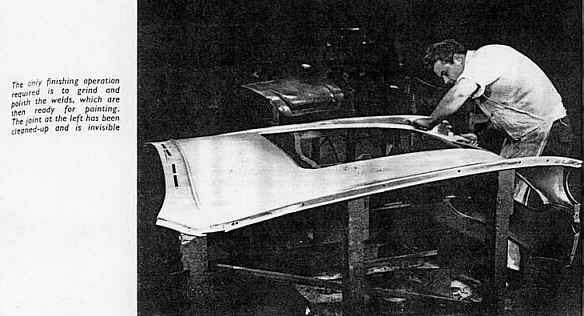

When the two main panels are completely assembled,

they are prepared for finishing by a skilled panel beater. Irregularities

in the panel surfaces caused by handling, or due to marks in the original

sheet, are planished out and the weld beads on the outer surfaces are ground

flush, filed, scraped and polished, as illustrated. So good is the

finish at this stage that no sign of the weld is visible, and no solder

or other filling is required before painting. The neat underbeads,

as already mentioned, are left untouched to provide a degree of reinforcement.

They have a useful incidental function in that, in the event of subsequent

accidental damage too severe to be beaten out, they delineate the exact

position for cutting out and welding in a replacement panel.

Range of torches

Although the equipment used by Jensen Motors

Ltd, for this high-class work is simple and compact enough to encourage

its use in the smaller workshop and even for repair work where aluminium

or its alloys are concerned, its capacity for heavy work is considerable.

The water-cooled Mk 111 torch can weld continuously at 300 A, or higher

for intermittent duty. For sustained operation at high currents,

a water-cooled shield is available to replace the normal ceramic argon

shield. This modification makes possible the continuous welding of

aluminium up to ½ in. thick. With the ceramic shield, the

normal limit in aluminium is 3/8 in.

For even heavier work, the Mk V torch can

handle up to 600 A, while at the opposite end of the scale there is a simple

air-cooled Mk 11a torch for welding at up to 100 A. The usefulness

of the Argonarc technique has been greatly extended by the introduction,

chiefly in response to the demands of the aircraft industry, of two miniature

models, known respectively as the swivel-headed torch and the pencil torch.

Of extremely compact design, the pencil torch is only about 5 in long,

and is held in the hand in the same manner as a pencil. The cable

is fed through the bore of the transparent argon tube, which enhances the

ease of handling. This model, and the swivel-headed version which

incorporates a head that can be adjusted through an angle of 48 deg, can

be applied and operated in the most awkward locations. Despite their

small size, they can work intermittently at 75 A. They can safely

be used on stainless steel and other metals down to 0.02 in thick, producing

neat and sound welds.