Fabrication of the new transmission tunnel, which needed to be higher to clear the auto trans.

The completed cover which also acts as a over plate for the left hand drive pedals and column.

I have had an aluminum radiator constructed to utilize all of the available space to ensure adequate engine cooling. The radiator has locating pins welded to the bottom tank and sits on rubber bushes. Austin Healey sway bar link bushes will be used in the top mounting to insulate noise from the thermo fan that will be mounted to the front of the radiator / air conditioning condenser and remove any stress on the radiator from scuttle shake.

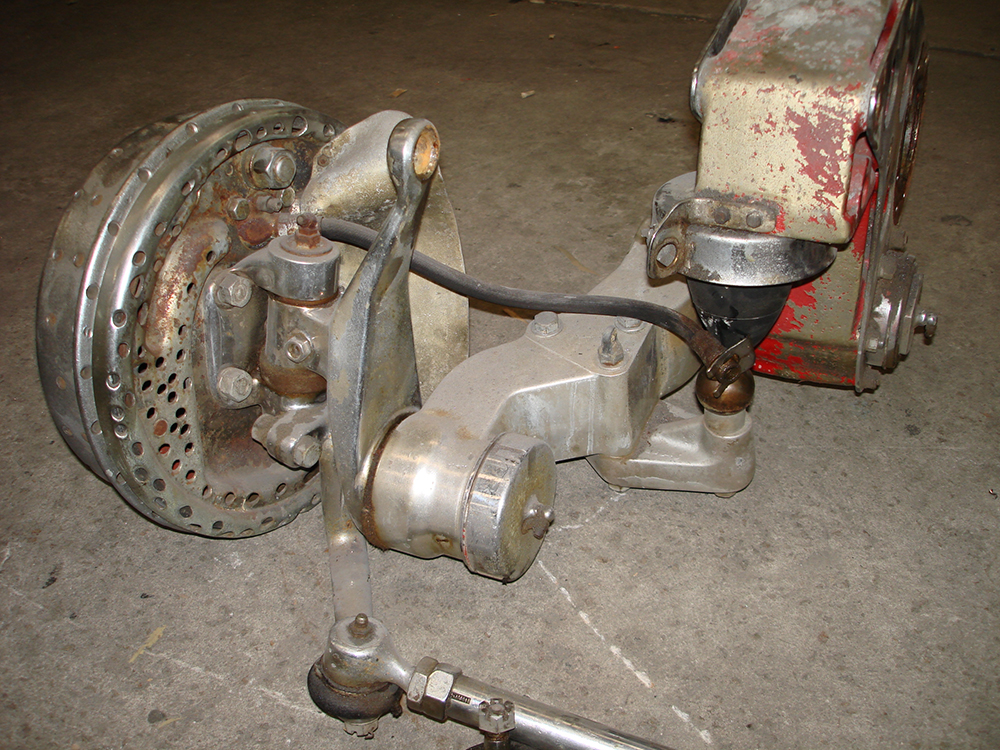

One of the front suspension units, the drums and backing plates have been significantly modified for cooling during the Roy Stetina era rebuild. The brakes will be upgraded to disc as part of the Vicroads registration requirements.

Construction has started on a rollover jig so I can get on with finishing the welding and repairs more easily. I have fabricated plates to bolt to the suspension mounting tube.

The completed rollover jig, I'll probably add a little more bracing at the rear as the bumper mounts are a bit far in from the jig.

View from the underside, I can get on with welding and removing the remaining body deadener

An extra cross member needs to be added below the engine, which will be removable should the engine sump ever need to be removed while in the car. A template is being used to pilot drill the holes and internal threaded rods will be welded in place.

Cross Member installed ready for welding. The original cross member normally fitted at the rear of the engine has been modified and re used. Also shown are the engine mounts and radiator mounts.

Underside showing the full chassis layout

Side on in the rollover jig, showing the beautiful lines of the coupe body

Panhard rod mounting point, the hole is worn oval, and will be repaired. Also shown is how the inner wheel arch is cut away so the outer body could be repaired. Rather than closing the inner guard at the wheel arch as original, to avoid the dirt and rust trap it created, the inner guard will be extended straight out, flanged with a small gap to the outer panel and seam sealed after painting.

Page 13

Home