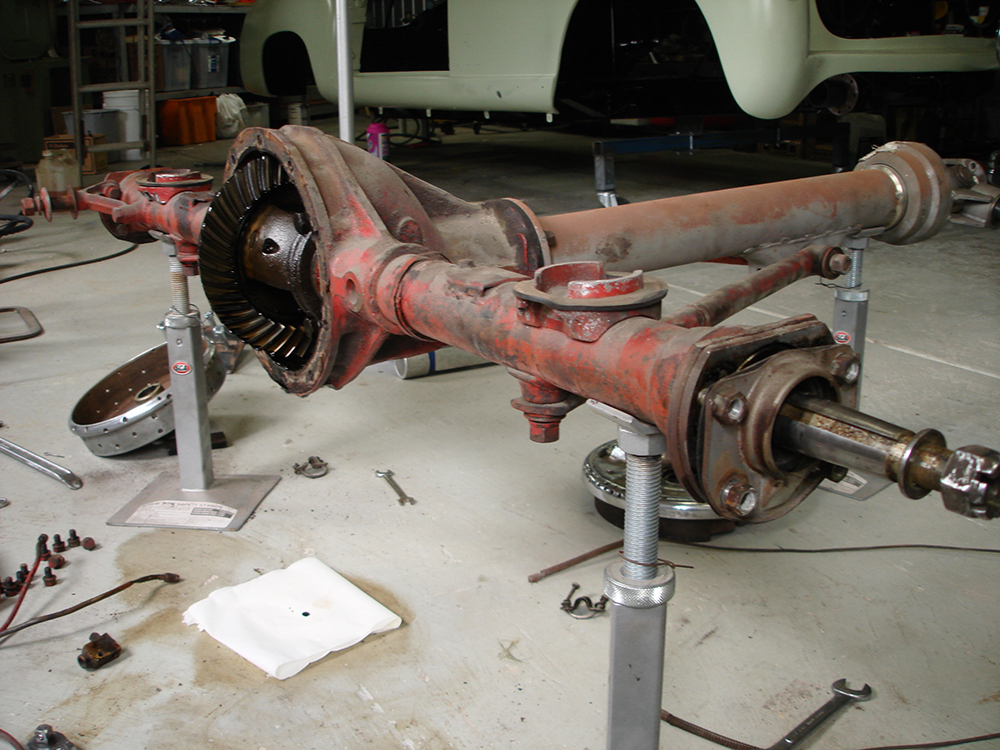

The diff ready for overhaul and conversion from standard ratio to 3.2 to suit the overall final drive.

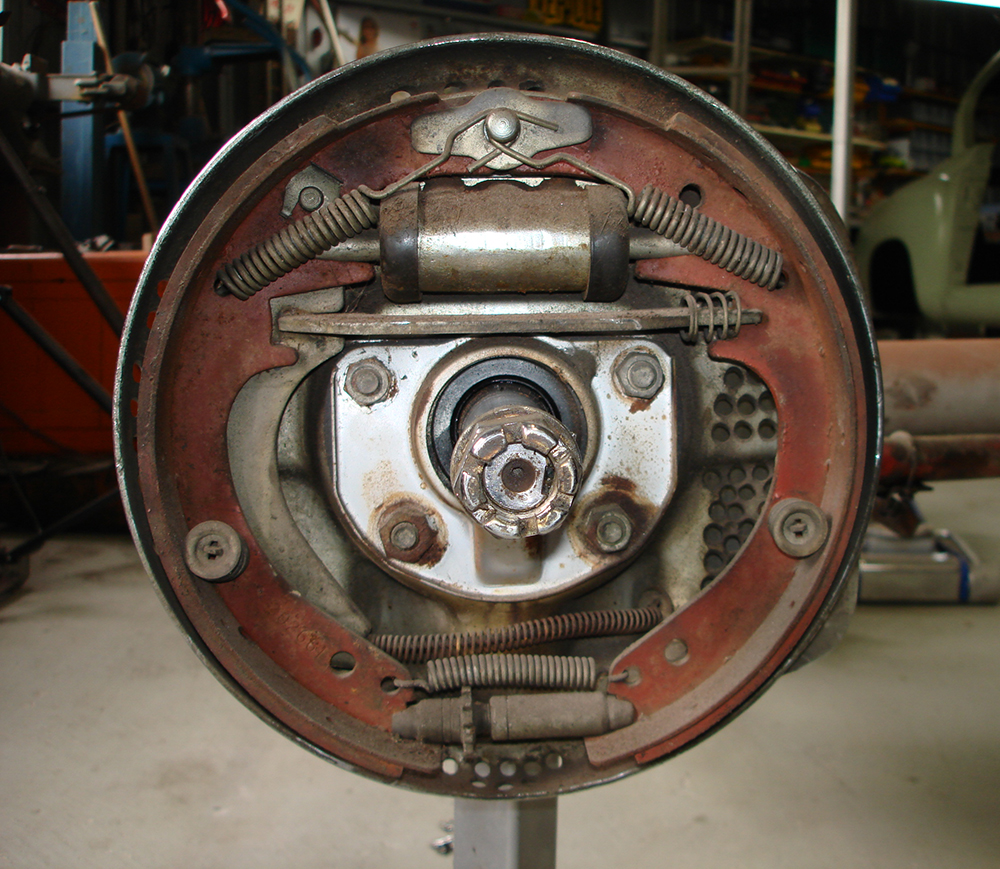

The standard Nash Healey rear brakes, except for the ventilation holes.

Axle end and hub with riveted on brake drum removed, note the damage to the axle where the threads are worn away.

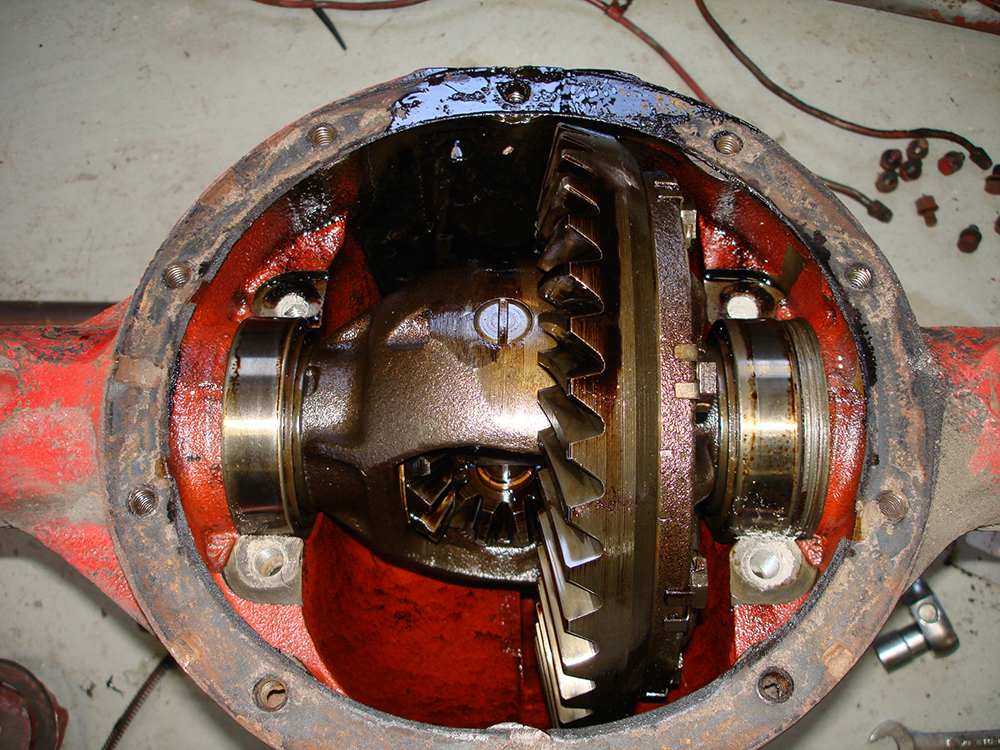

Everything is in good condition as the car only ever traveled about 80,000 miles.

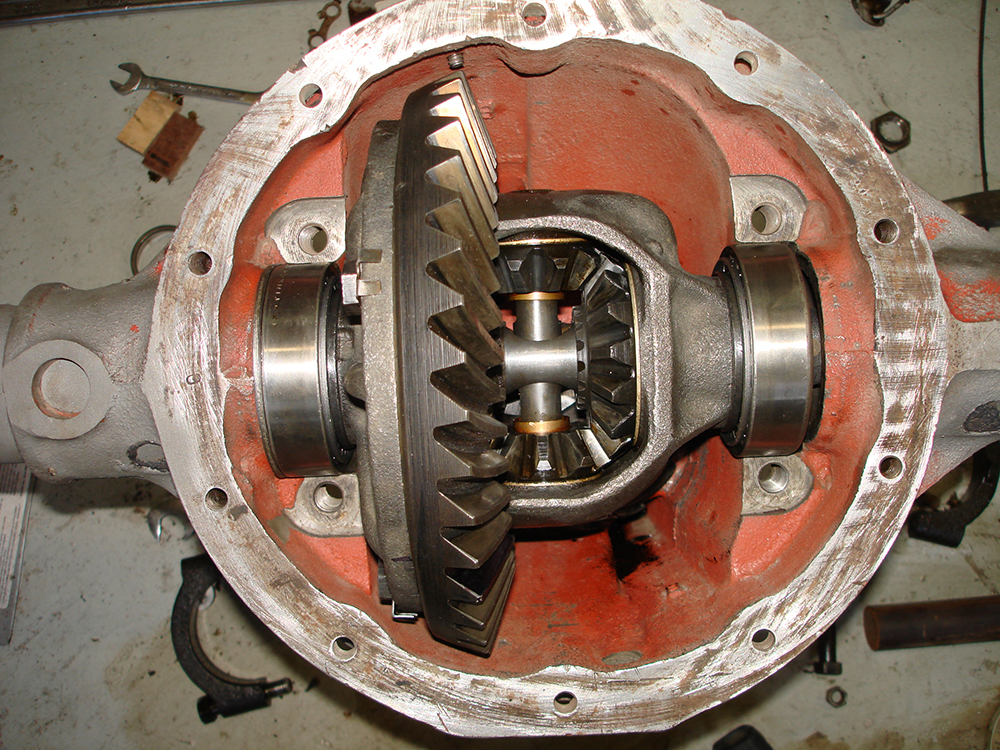

The standard diff pinion below and the 3.2 pinion above quite a difference! The 3.2 pinion has a step to locate the right side bearing where the standard one uses a spacer.

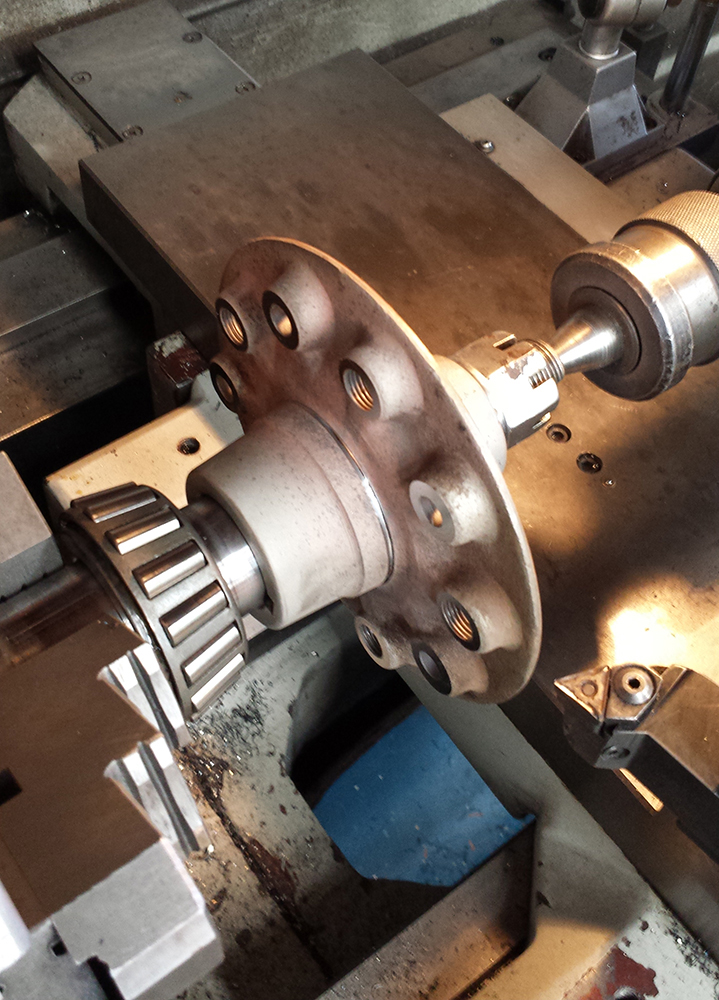

The new ( second Hand ) gear set in place with new bearings. Here I'm working out the mesh and preload on the bearings. Note the block on the axle centerline. On these cars the axles from both sides touch the block and have tapered roller bearings on the axles ends. End float in the axles is set at the end flanges.

Tool for tightening and torquing the pinion nut.

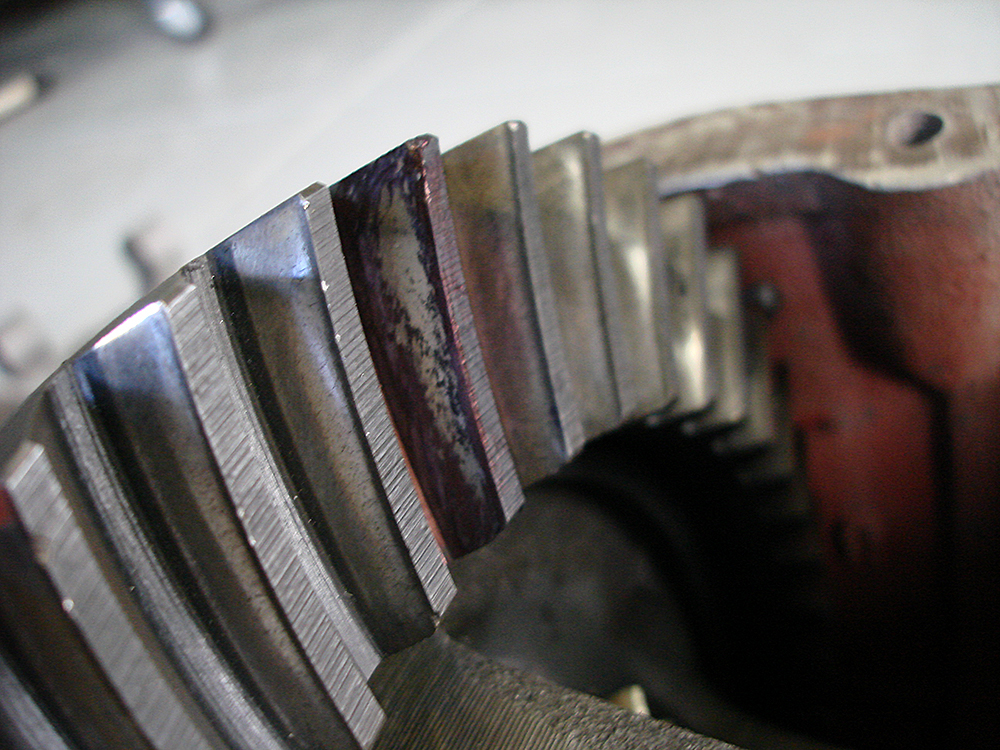

This was about the best contact patch I could achieve using the second hand crown wheel and pinion.

Meanwhile the engine is finally completed.

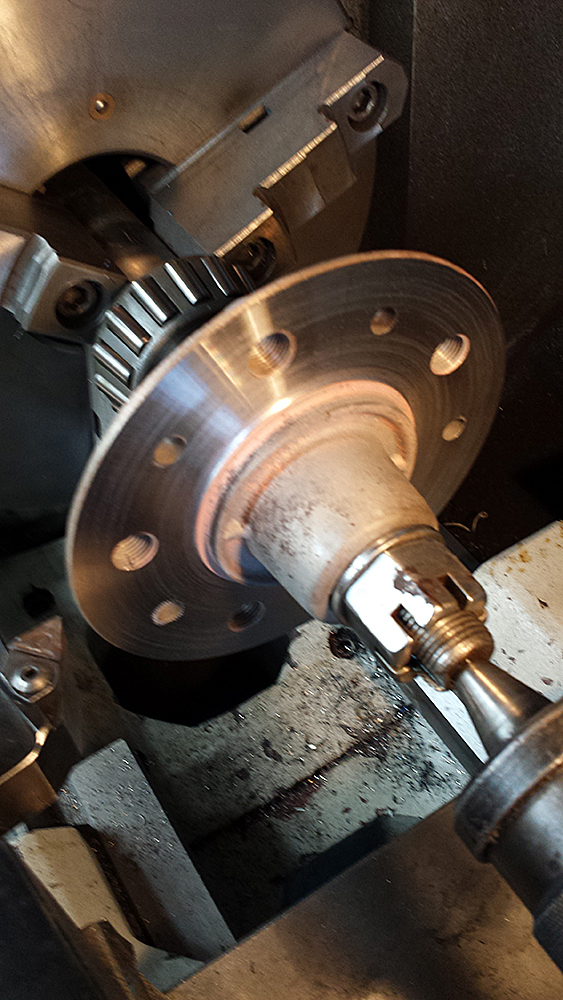

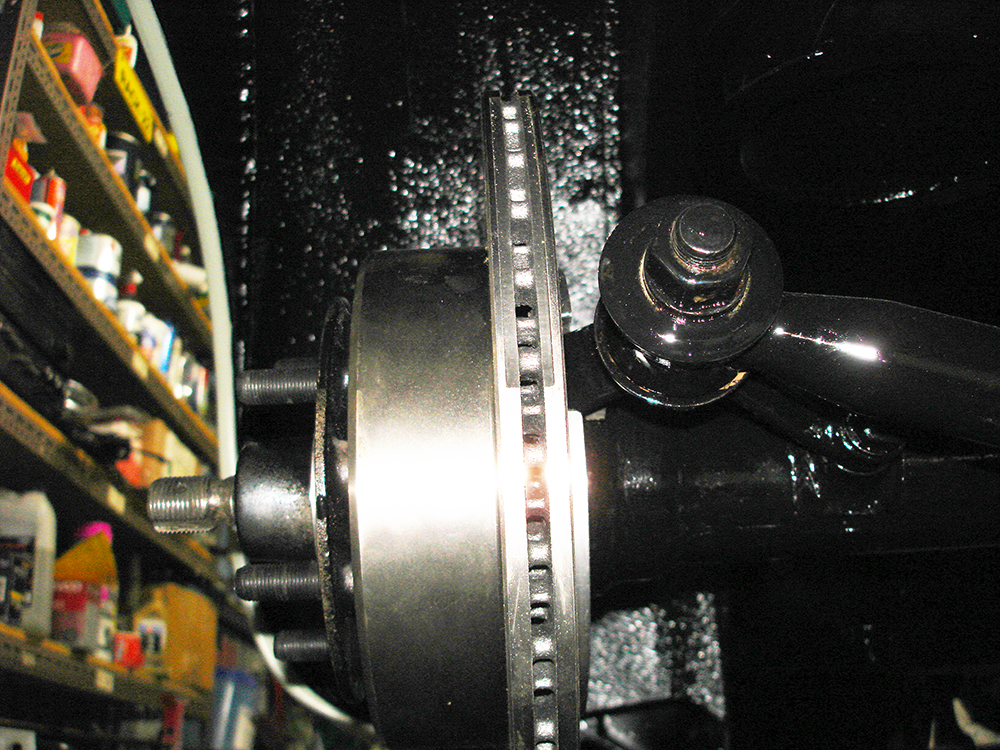

For the rear disc brake conversion I need to make sure everything runs true, so here I'm re machining the inner face of the axle flange where the discs will mount. The rear hubs are mounted on a tapered end axle on these cars

The front face also cleaned up while in the lathe, but it was basically true anyway.

Meanwhile I have been working on the front suspension units. The car had previously been modified by Roy Stetina in the early sixties to take needle roller bearings on the king pins and the thrust bearing to lighten the steering effort. The system worked well as the steering was quite light when I had the drive train installed for setup. In those days the equipment was not available that is now so I have made some changes. Roy welded nuts to the needle bearing housings, so I have replaced them and drilled the ends with a solid carbide drill and nuts inside the bearings hold the grease nipple. I turned new king pins to suit and pressed on proper inner bearing races. A 1/8 hole through the center of the king pin will allow grease into the races and out into the thrust bearing.

The front suspension unit prior to dis assembly

This was the arrangement before my modifications. You can see the needle bearing cage id blue from the heat applied to weld in the nut to hold the grease nipple, and that grease had to travel down the groove in the king pin. I didn't like the idea of a grooved shaft inside a needle roller bearing.

Suspension now all fitted and trial fitting of the wheels and Avon 70 profile tyres. No brakes yet!

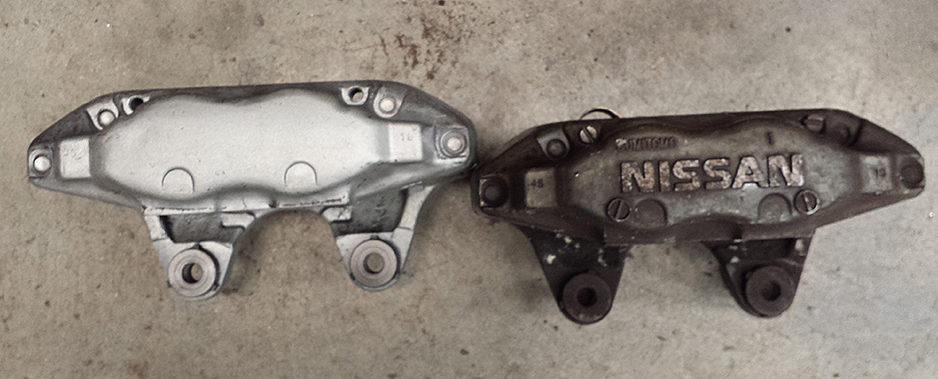

After considerable searching I have decided to adapt Nissan Skyline GT-

R32 brakes. These are the front 4 pot calipers

Nissan GT-R 32 Rear calipers

The front caliper after de branding

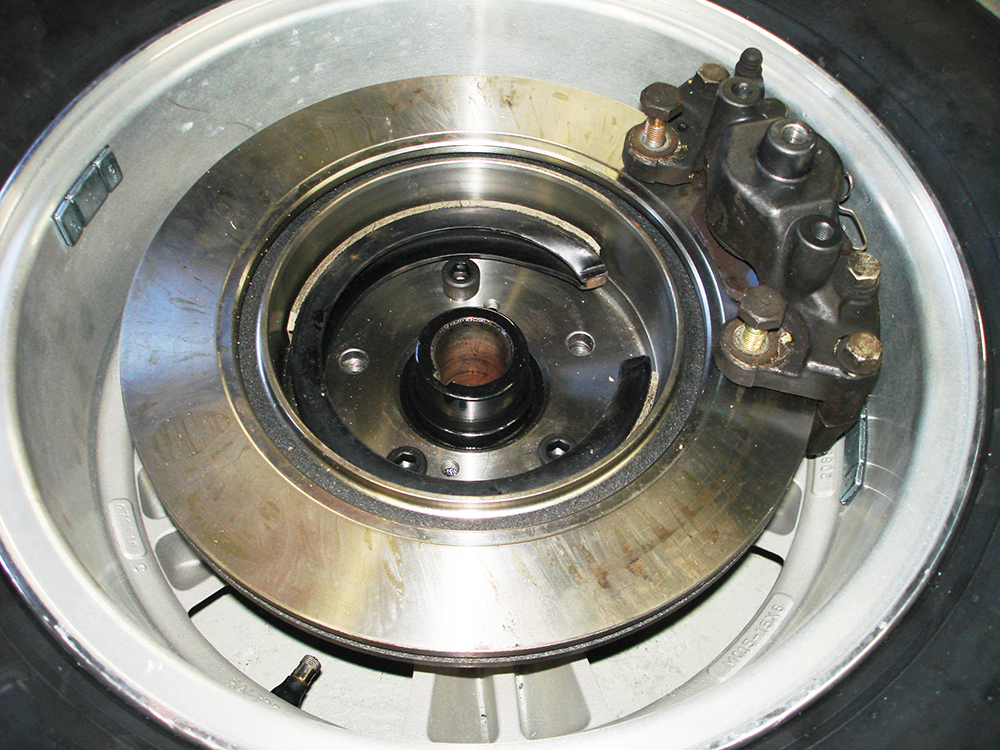

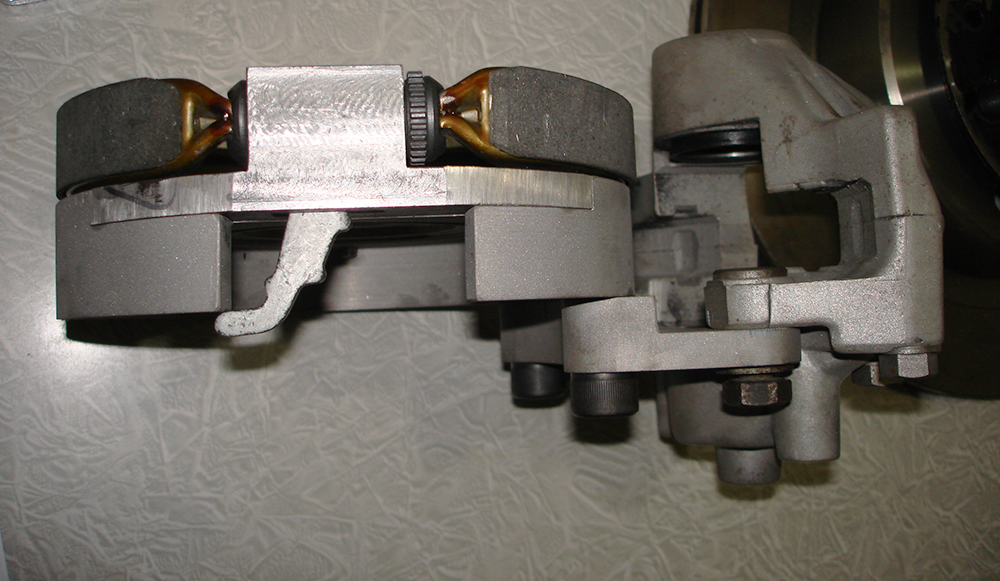

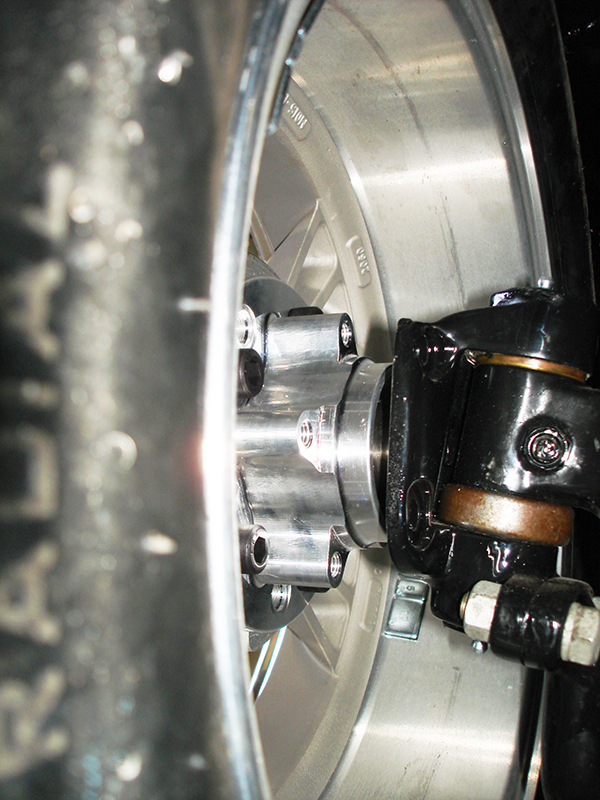

The rear Nissan disc and caliper trial fitted in the

wheel. The Nissan drum style park brake was quite complicated so I have

decided to go my own way and adapt a "Banksia" style park brake

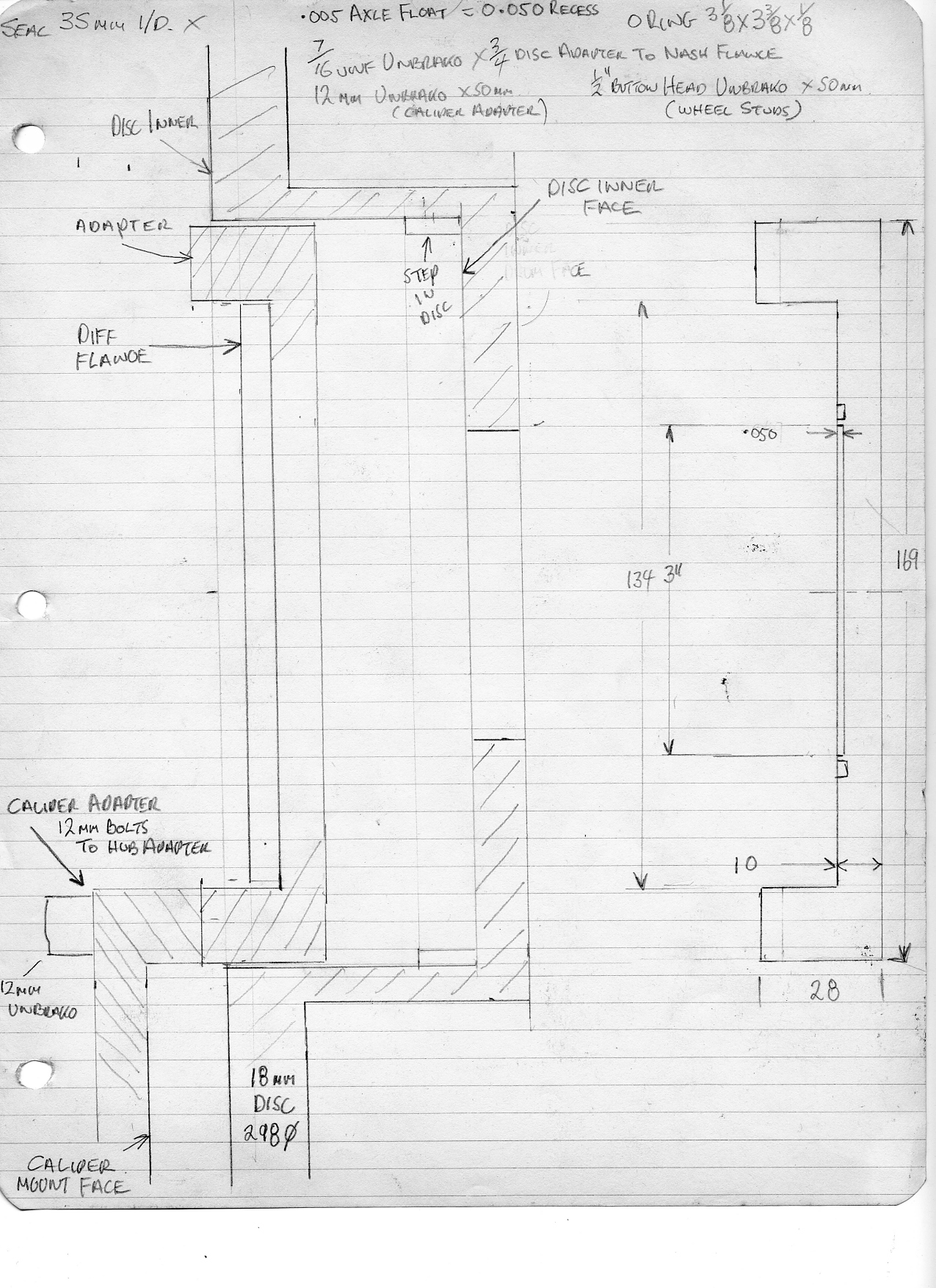

Sketch of the basic rear brake adaptation. The Nash rear

wheel bearings were greased rather than lubricated by diff oil. The

adapter will set the rear wheel bearing end float and seal the axle

housing flange so the bearings will be lubricated with diff oil.

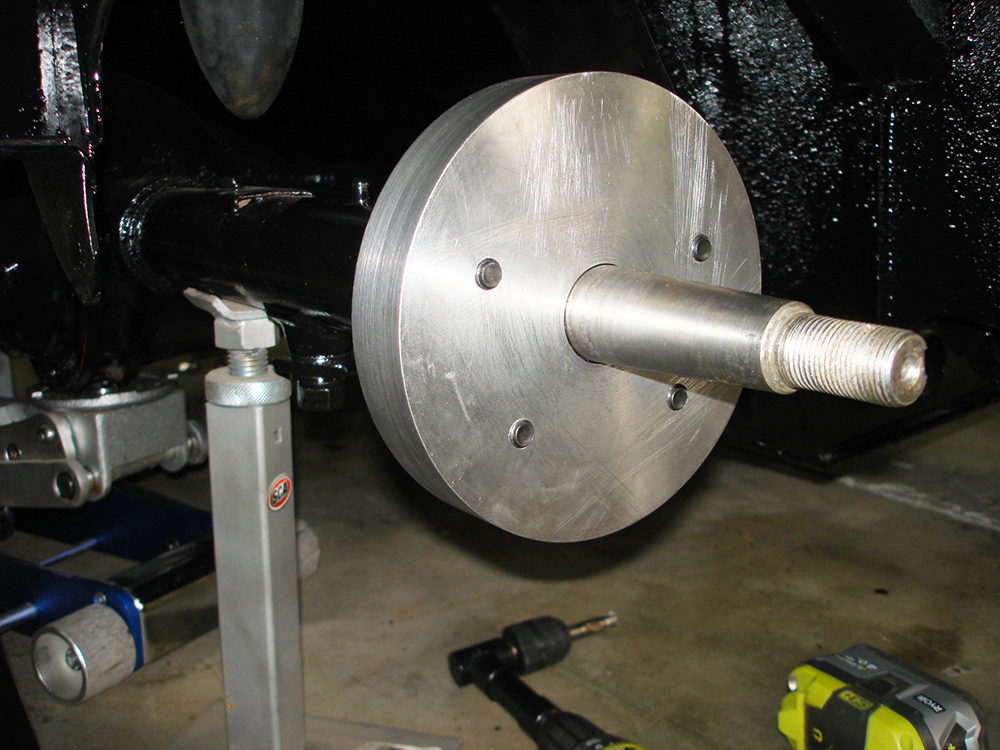

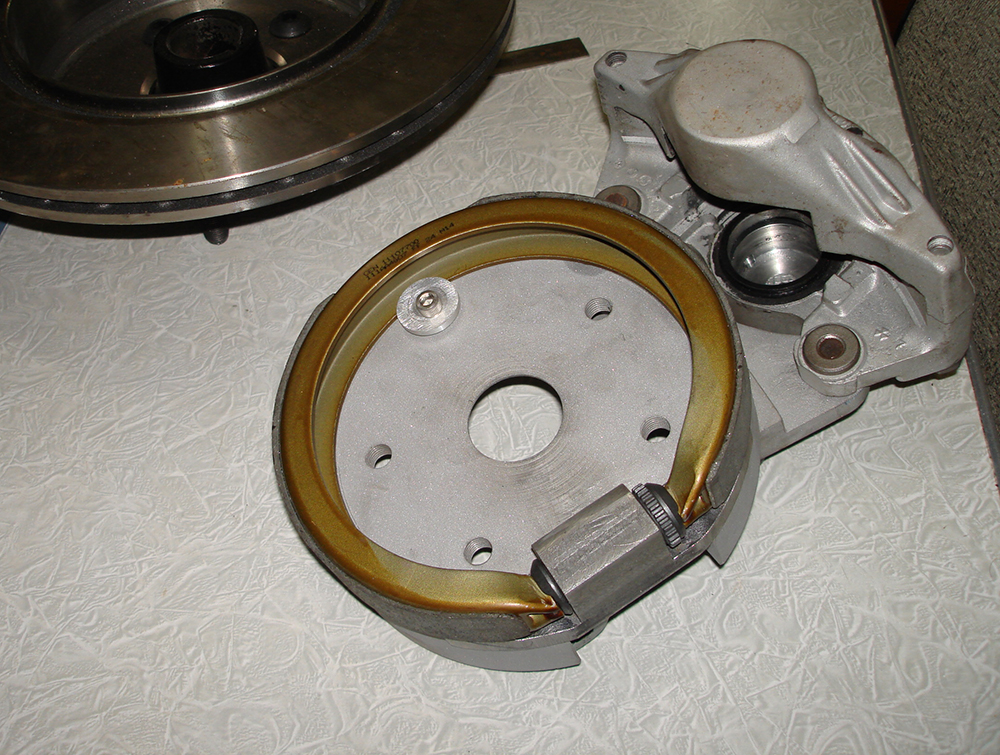

The adapter flange machined and in place

Inside view of the adapter flange with O ring groove for oil sealing and a recess for the main oil seal

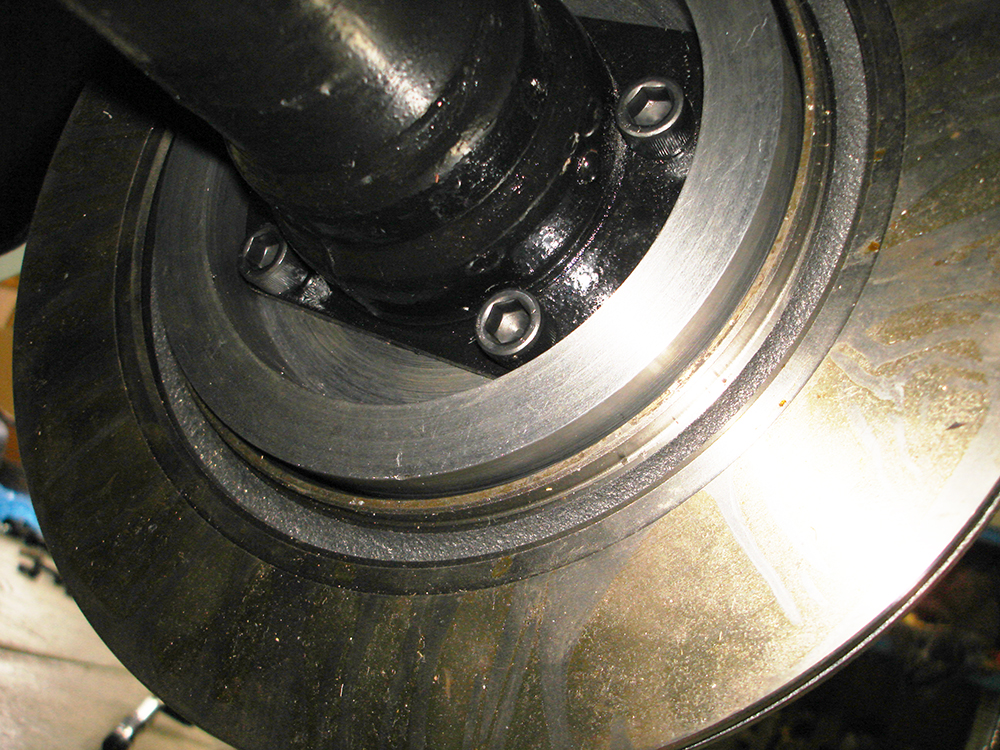

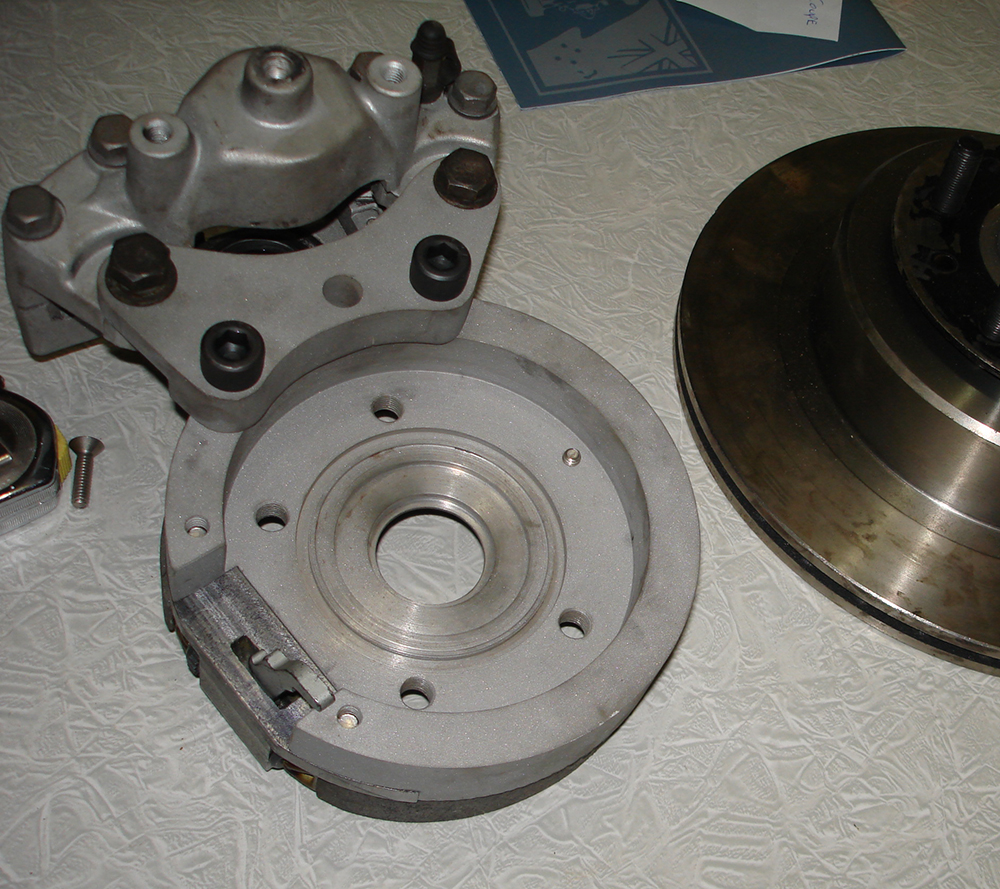

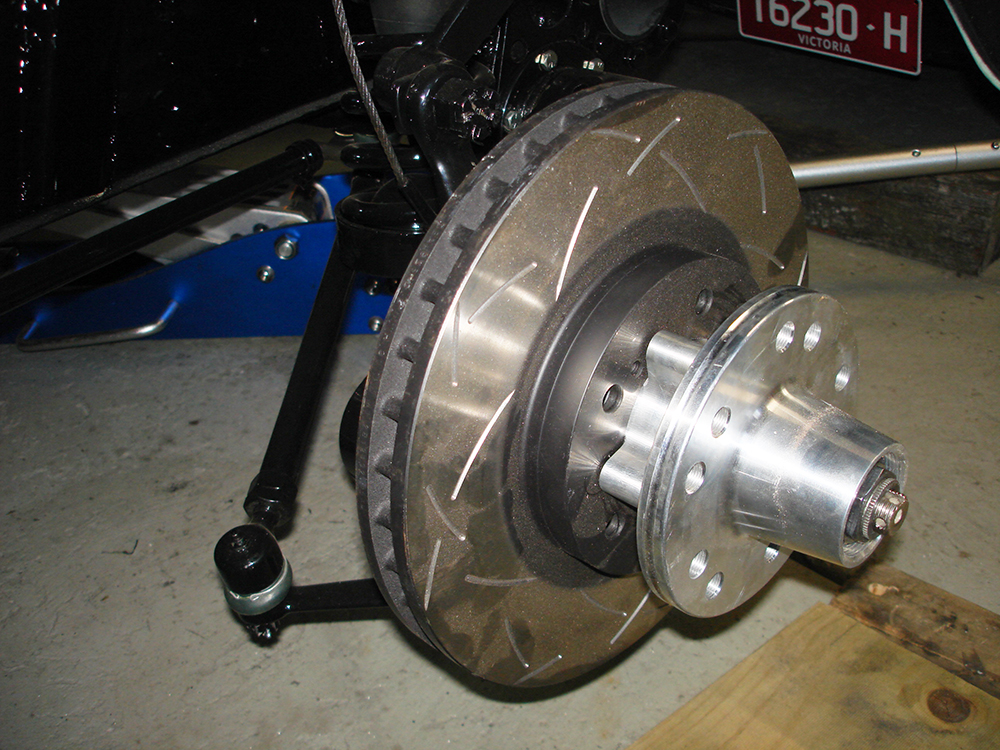

The basic assembly in place on the diff housing prior to fitting the park brake actuator

The Skyline ventilated rear disc

The Banksia park brake mounted on the adapter. The shoe

is from a Pontiac Grand Prix. All of the cars that use this system seem

to use the same PBR components for the spreader, just the spreader

housing changes. None of the available housings suited so I have made

my own housings to suit.

Rear view showing the actuator lever for the hand brake cable

Side view of the assembly

Rear brakes completed

Rear view of the right side assembly showing the park brake operating lever

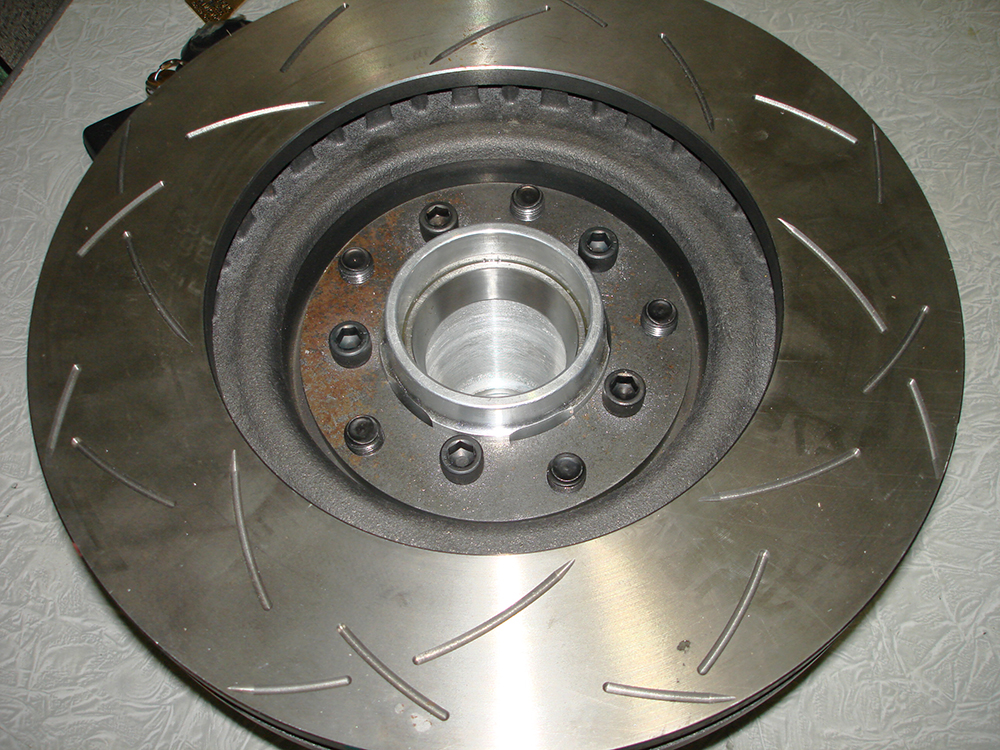

Front brakes, I quite quickly found the the original hubs were cast

iron. I felt this was not suitable for the tyre grip and braking force

the car would have, so Im using Wilwood billet alloy hubs with some re

machining to suit the Nash stub axle.

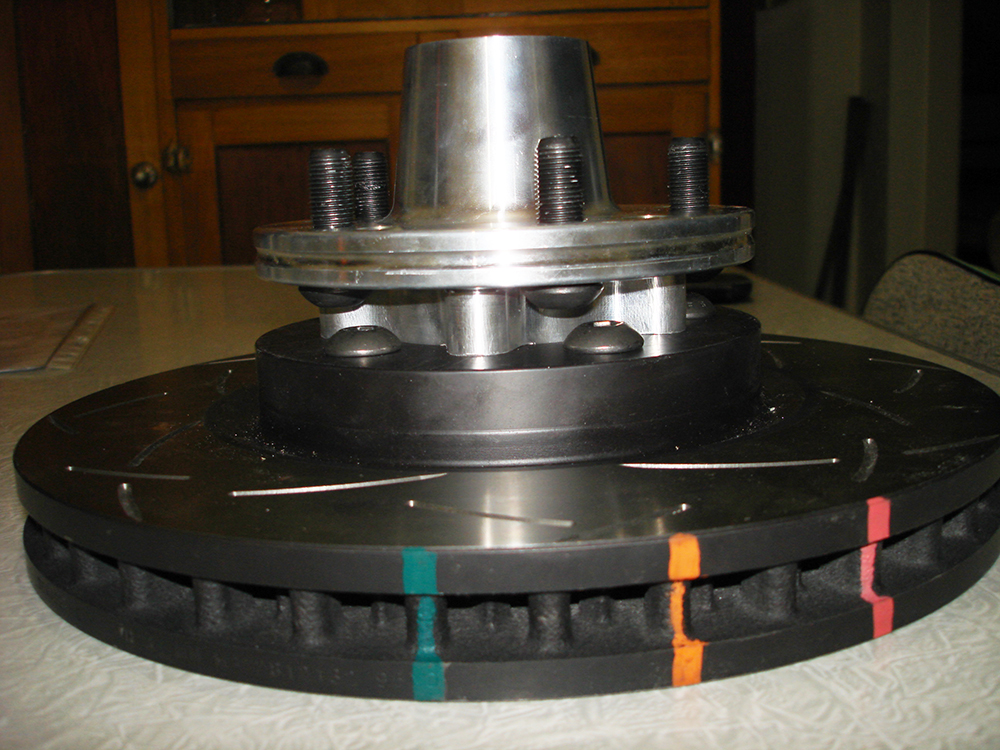

The Skyline disc mock up with the Wilwood hub.

A 10mm thick steel plate at the rear of the disc adapts the standard disc to the Wilwood disc mounting face

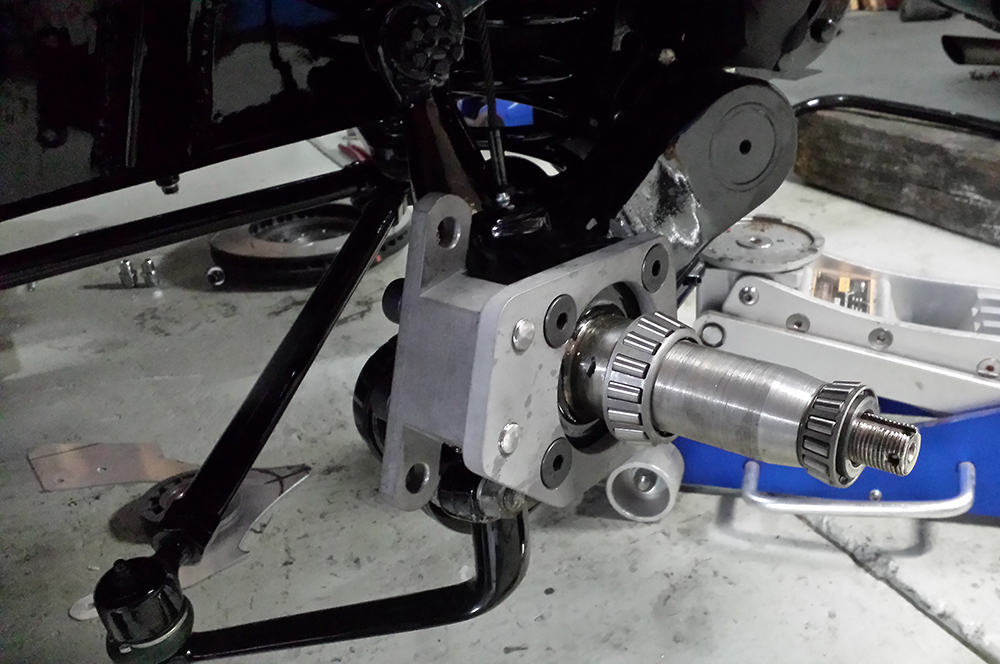

Caliper mounting adapter fitted to the stub axle. I also decided to

make a spacer between the inner and outer wheel bearings so the

bearings will be shimmed to set clearance. As the adjustment nut will

be fully tightened it will increase the strength of the stub axle.

Front brakes completed.

Nash Healey parts needed

2 x license plate lamp

1 x rear windscreen stainless steel trim

1 front windscreen chrome trim

1 x door key lock

1 x boot lid handle and lock

2 x interior door handles

1 x window winder handle

5 x interior door handle escutcheon sets

2 x exterior door handles

1 x fuel filler door

1 x front windscreen interior alloy molding bottom and sides

1 x grill badge chrome surround

1 x Rear vision mirror

2 x rear wing dummy vents

Page 16

Home