Dismantling the engine revealed

what I had expected. The engine has done very little work. The front and

rear engine plates were bent from the accident, the rear plate has the

shape of the engine flange embedded in it's surface from the force of the

impact. I gave the bores a light hone and fitted new rings to the pistons,

even though I found no dimensional difference from the old ones. The big

end and main bearings are in perfect condition so I reused them. Five of

the cam followers had bad pitting on the ends so I had them reground (

with the correct domed surface ) I decided to have the cam checked, but

it turned out to be unaffected. Everything only needed to be been cleaned

and reassembled. I replaced all the gaskets and seals, including a modern

style head gasket.

One of the engine mounts

was also bent and badly repaired, in fact it snapped when I attempted to

straighten it. Once again my brother Dennis came to the rescue with a spare

mount from an Austin A70 engine he bought for parts 20 odd years ago. The

generator (also supplied by Dennis) and water pump have been overhauled,

both getting new bearings, and a set of brushes in the generator.

The image below shows a

small modification I have made to the rocker cover mountings. Instead of

refitting the original rubber washer and cup washer under the attachment

bolts, I had small sleeves machined with an "O" ring groove in the bore

and silver soldered them to the cover. Hopefully this will lead to less

oil leaks!

The image below shows the

modification I have made to the timing case seal. The original felt seal

wasn't exactly the ideal arrangement, so I had a steel ring machined to

take an oil seal and silver soldered it to the case.

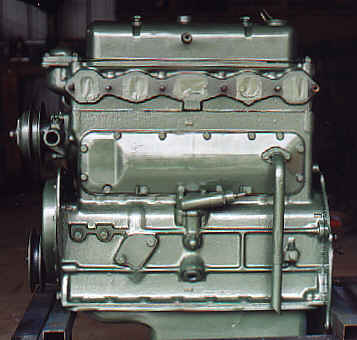

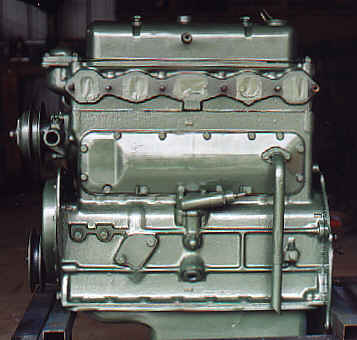

As can be seen in the images,

the engine is now painted the correct Healey green and has tonight been

fitted back into the car.

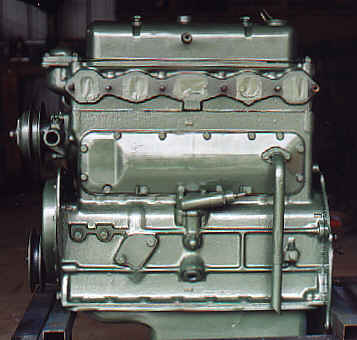

As can be seen in the images,

the engine is now painted the correct Healey green and has tonight been

fitted back into the car.

Page

13

Home