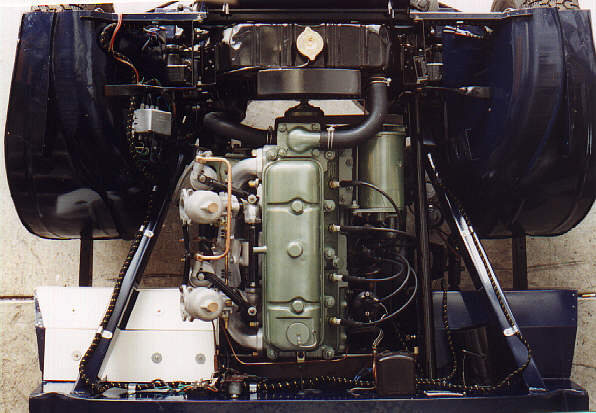

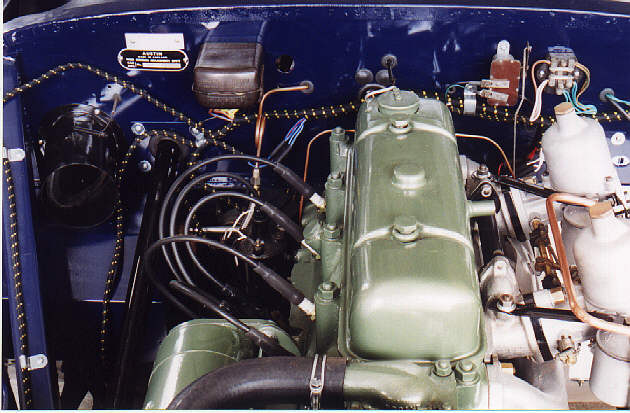

I think I have the wiring layout right (thanks Ward), but would be happy to hear from anyone who disagrees on any aspect of the engine bay layout. I'm still getting round to making the brass eye used to attach the copper oil line to the firewall and the cable bracket for the cold air intake. I have deliberately taken the wiring for the flasher unit inside the cabin, rather than mounting it in the engine bay, as a result of suggestions that is is easier to hear the tick which reminds the driver that they are on. The two wires for this can be seen at the extreme right of the image below.

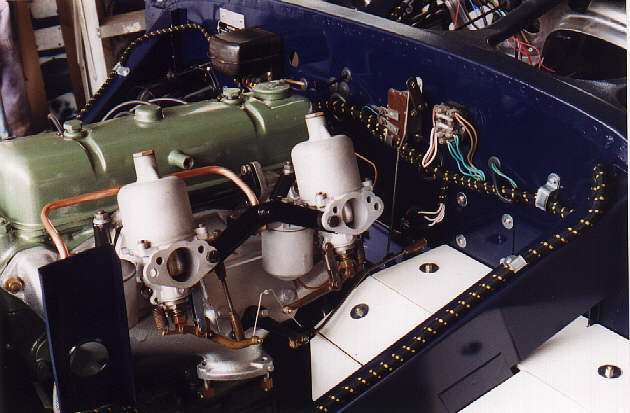

One of the exhaust manifold outlet flange studs, which at some point had at some point been re tapped (at an angle) had to be plugged and re tapped square. The carburetors are from an old Austin as they were not supplied with the car. I sent the carburetor bodies to Midel in Sydney for re bushing and they were able to supply me with all of the components I needed from stock to refurbish them, including the correct choke arms. The copper line between the carburetor float bowls I fabricated myself. I'm not sure that I have the throttle linkages original, but this layout provides a long pedal travel and at rest, the pedal is level with the brake pedal.

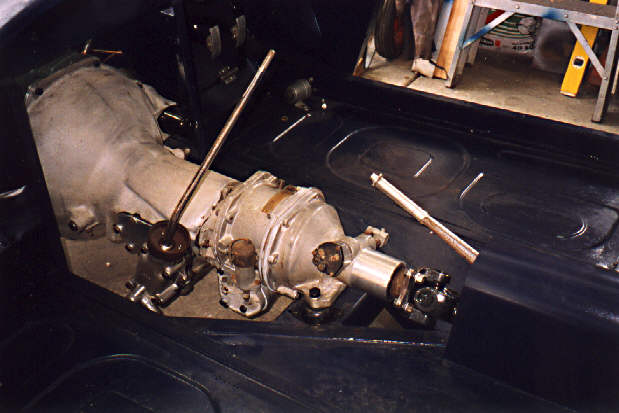

The gearbox had unfortunately been stored without any oil in it since the 50's. A build up of condensation in the housing had caused surface rust on the bearings and jammed the shift cross shaft in the side plate. A new cross shaft was machined, hardened and ground and the input shaft and main shaft bearings replaced. Otherwise the condition of the gearbox was excellent. The gearbox rear mounts which are incorporated into the Laycock overdrive unit, had been broken off when the car was crashed and welded back on. The heat from welding caused significant distortion in the housing that wasn't picked up at the time. The housing has now been re machined to correct this problem.

Page 14

Home